The parcel industry has seen immense growth in recent years with the rise of e-commerce and direct-to-consumer shipping. To keep up with increasing parcel volumes, companies are turning to parcel automation to streamline operations. Parcel automation refers to the use of technology and equipment to handle, sort, and route parcels with minimal human intervention.

Types of Parcel Automation

There are a variety of technologies that fall under the umbrella of parcel automation:

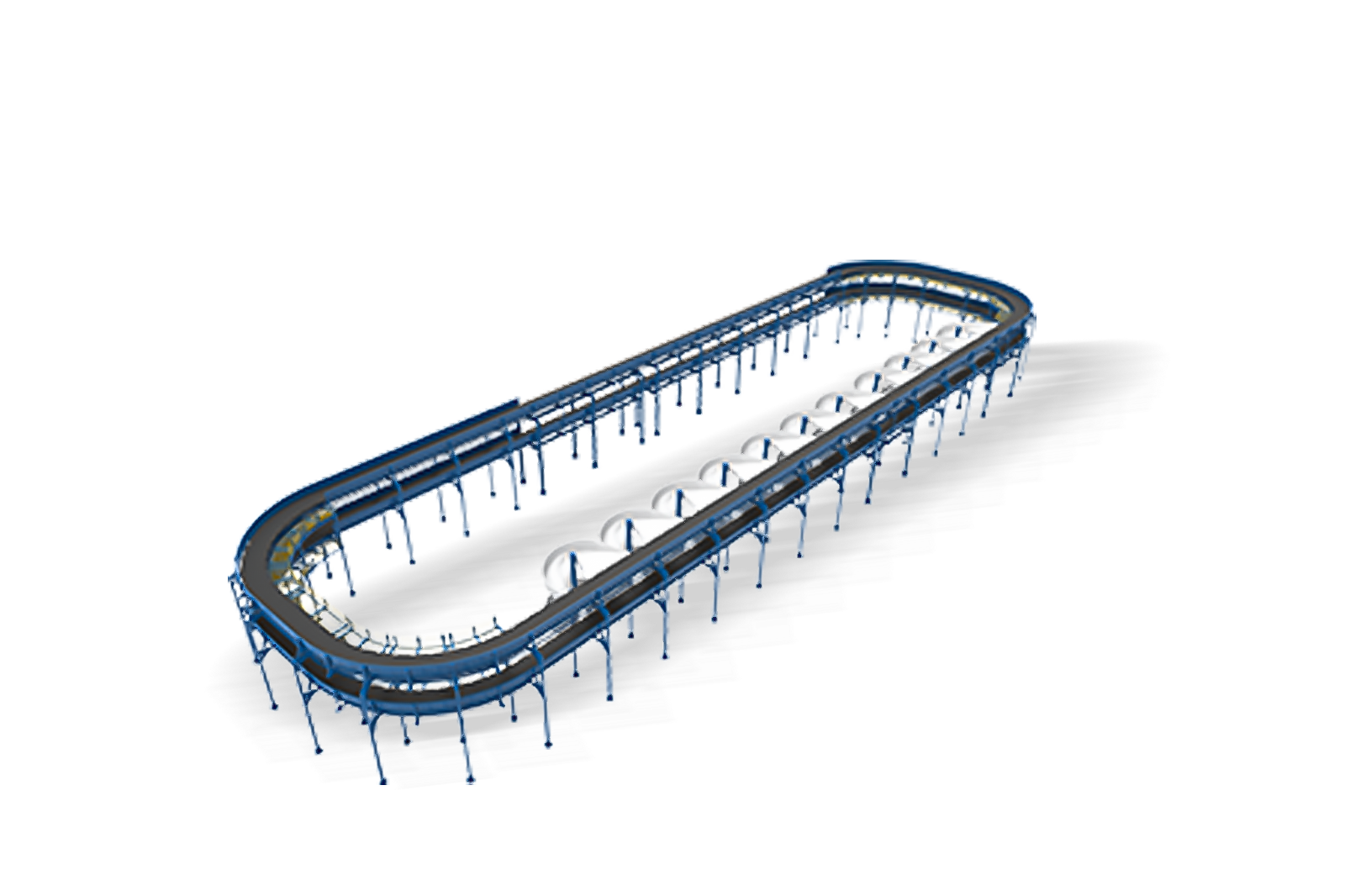

1.Conveyor Systems

Conveyor systems move parcels between workstations and different areas of a facility. They help optimise workflow and reduce the need for manual labor. Common types of conveyors used in parcel sorting include belt conveyors, roller conveyors, incline conveyors, and cross-belt sorters.

2.Dimensional Weighing Systems

These systems automatically measure the dimensions and weight of parcels. This data can be used for shipping rate calculations and to ensure proper handling. Dimensional weighing improves efficiency and accuracy over manual parcel measuring.

3.Automatic Guided Vehicles (AGVs)

AGVs are self-driving vehicles that transport parcels around facilities. They follow sensor-guided paths and help eliminate the need for forklifts and other manual material transport methods.

4.Parcel automation

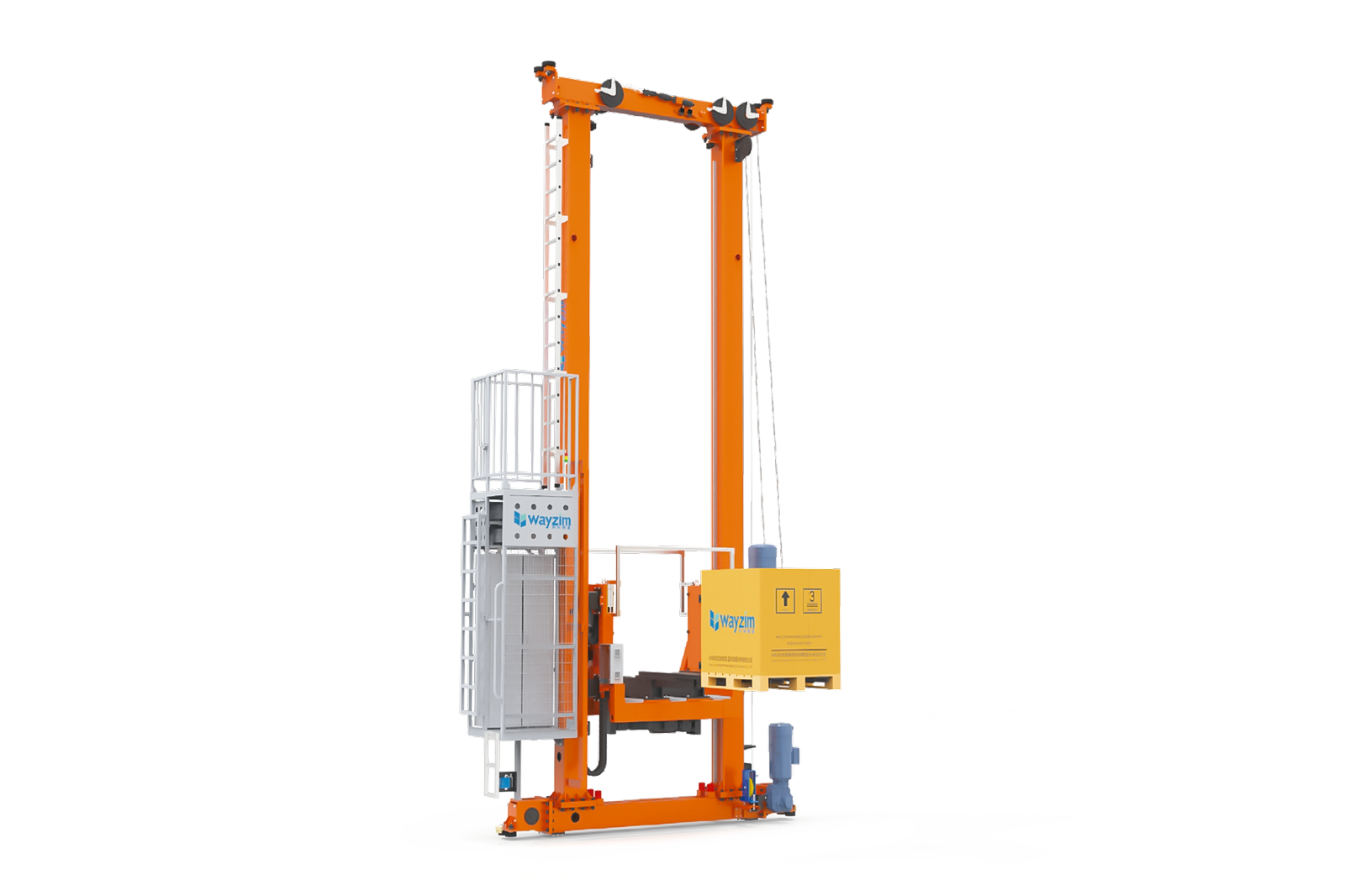

5.Automated Storage and Retrieval Systems

These systems use automated cranes and shuttles to store and retrieve parcels in facilities. They work like giant vending machines, moving inventory to workers to fulfill orders. Their high-density storage capabilities reduce real estate costs.

6.Robotic Arms/Pickers

Robotic pick and place technology speeds up repetitive tasks like moving parcels from conveyors to shipping containers. Robotic arms can work faster and more consistently than humans.

7.Computerised Routing Systems

Software directs parcels to their next destination – whether it’s a sorting station, packing area or vehicle. Tracking codes on parcels allow the systems to “read” each item and keep deliveries on the optimal path.

RELATED: Navigating the Future of Delivery: A Comprehensive Guide to Parcel Automation

Schedule a call with SmartlogitecX

Benefits of Parcel Automation

There are many reasons companies are embracing parcel automation.

1.Increased Throughput

Automation allows warehouses and fulfillment centers to process significantly more orders and parcels each day due to the speed and efficiency advantages. Conveyors, robots and other technologies far outpace human pace alone.

2.Enhanced Accuracy

Mistakes from human fatigue, reading errors, etc are greatly reduced. Automated weighing, scanning and routing all have much higher accuracy rates than manual operations.

3.Smaller Labor Requirements

While parcel automation requires technical staff to manage, it reduces the number of people needed for manual sorting, moving and tracking activities. Fulfillment centers can do more with smaller workforces.

4.Better Use of Space

Automated storage and retrieval systems allow companies to use vertical space more efficiently than ground-floor manual storage. Higher-density warehouse storage reduces facility and land costs.

5.24/7 Operation

Machines don’t need breaks or sleep! Automation allows parcel facilities to run around the clock if desired. This allows companies to maximize throughout.

6.Safer Working Environment

Automation reduces heavy lifting injuries and other labor-intensive tasks that commonly contribute to warehouse injuries. Workers can focus on more cognitive tasks.

The rapid growth of e-commerce makes parcel automation a must for many parcel delivery companies and retailers. Leveraging the right technologies allows them to keep up with demand while controlling costs and improving working conditions. Parcel automation will only continue evolving in speed and capabilities, making it an essential long-term investment for players in the industry.

RELATED: Parcel Automation: Transforming the Delivery Landscape

Frequently Asked Questions About Parcel Automation

1.What are the key technologies used in parcel automation?

Some of the major types of parcel automation include conveyor systems, automated storage and retrieval systems, robotic arms, dimensional weighing systems, AGVs and computerised routing systems. These technologies are designed to streamline parcel handling and sorting.

2.How does parcel automation increase efficiency?

– Higher throughput speeds with automated conveying and sorting

– Less errors thanks to automated measuring, scanning and routing

– Reduced labor requirements with machines handling repetitive tasks

– Maximised warehouse space with dense, vertical storage

– 24/7 operation without breaks

3.How can parcel automation reduce costs?

– Smaller labor force needed, with machines doing bulk of manual work

– Reduced warehouse space needed thanks to dense automated storage

– Faster processing leads to higher sales volume and lower per-parcel costs

– Lower insurance premiums due to improved worker safety

4.What parcel automation technologies are emerging?

Some newer and evolving parcel automation technologies include: mobile delivery robots for last mile deliveries, advanced artificial intelligence for optimised load planning and delivery routing, exoskeletons to assist workers, and drone delivery in some locations.

5.What skills are required to manage parcel automation?

Important skills needed for overseeing parcel automation include technical knowledge of equipment maintenance and repair, computer and software proficiency, analytics, logistics optimisation, mechanical engineering and project management. Facilities look for well-rounded teams to get the most from investments in automation.

Step into the future with SmartlogitecX, a WayZim Technologies venture, reshaping Warehouse Automation in Australia and New Zealand. Our mission is to provide you with advanced, efficient warehouse solutions that are a step ahead. SmartlogitecX combines global tech insights with local market expertise. Ready to upgrade your logistics? Our sales team is on hand to craft your ideal automation strategy.