When it comes to managing a warehouse, finding the perfect balance between efficiency and productivity is crucial. With the rise of automation, warehouse managers can now harness the power of SmartlogitecX automated warehouse solutions to streamline their operations and take their business to the next level. In today’s fast-paced and competitive market, manual warehouse processes can lead to errors, delays, and increased labor costs, which can ultimately impact a company’s bottom line. However, by implementing automated warehouse solutions, businesses can significantly improve their warehouse operations, increase efficiency, and reduce costs.

Automated warehouse solutions refer to the use of technology and machinery to automate various warehouse processes, such as storage, retrieval, and shipping. These solutions can range from simple conveyor belts, conveying devices with the belts as the carriers, which support the conveying of various regular, irregular, light, and heavy materials, to complex robotics and artificial intelligence systems. The primary goal of automated warehouse solutions is to increase efficiency, reduce errors, and improve productivity. By automating repetitive and labor-intensive tasks, warehouse staff can focus on higher-value tasks, such as customer service and inventory management. Moreover, automated warehouse solutions can operate around the clock, reducing the need for overtime and increasing productivity.

schedule a call with smartlogitecx

The benefits of automated warehouse solutions are numerous. Firstly, they can significantly increase the speed and accuracy of warehouse processes, allowing businesses to meet growing demands and reduce lead times. Secondly, automated warehouse solutions can improve productivity by automating tasks such as picking, packing, and shipping, freeing up staff to focus on higher-value tasks. Thirdly, automation can reduce errors, minimizing the risk of damaged goods, lost inventory, and shipping errors. Finally, automated warehouse solutions can help reduce labor costs, energy consumption, and maintenance costs, resulting in significant cost savings over time.

RELATED: Automated Warehouse Solutions: Streamlining Operations for Efficiency and Productivity

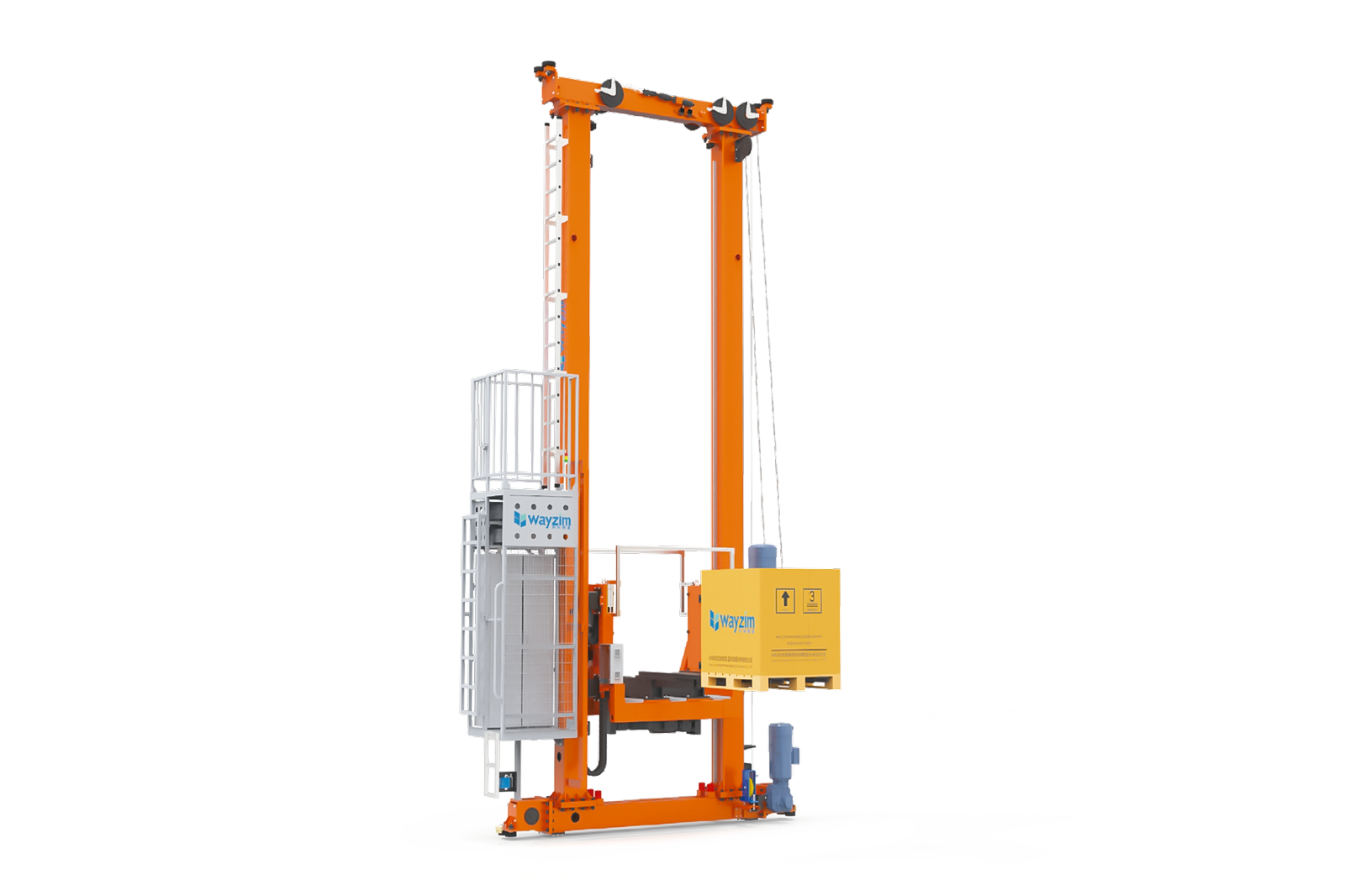

There are various types of automated warehouse solutions available, each designed to meet specific business needs. SmartlogitecX Automated Conveyor systems, for instance, can automate the transportation and sorting of goods, reducing labor costs and increasing efficiency. Robotic warehouse systems can perform tasks such as picking, packing, and shipping, freeing up staff to focus on higher-value tasks. Automated storage and retrieval systems (AS/RS) such as the ASRS Pallet Stacker Crane can store and retrieve goods, reducing labor costs and increasing storage capacity. Finally, warehouse management systems (WMS) can automate inventory management, order fulfillment, and shipping processes, providing real-time visibility and control.

When selecting an automated warehouse solution, businesses should consider several factors. Firstly, they should identify areas where automation can improve efficiency and productivity. Secondly, they should choose a solution that can grow with their business. Thirdly, they should ensure the solution integrates with existing systems and processes. Finally, they should evaluate the total cost of ownership, including maintenance and support.

Automated warehouse solutions are a game-changer for businesses looking to streamline their warehouse operations and improve productivity. By understanding the benefits and types of automated warehouse solutions available, businesses can make informed decisions and choose the right solution for their needs. With the right solution in place, businesses can reduce costs, increase efficiency, and improve productivity, ultimately gaining a competitive edge in the market.

RELATED: Optimizing Your Business with Automated Warehouse Solutions

Frequently Asked Questions

1.What is the cost of implementing automated warehouse solutions?

A: The cost of implementation varies depending on the type and scope of the solution. Businesses can expect to invest starting from $50,000 to more.

2.How long does it take to implement automated warehouse solutions?

A:Implementation timeframes vary, but businesses can expect a minimum of 6-12 weeks for simple solutions and up to 6-12 months for more complex solutions.

3.Will automated warehouse solutions replace human workers?

A:Automated warehouse solutions are designed to augment human workers, not replace them. Automation can help reduce labor costs and improve productivity, but human workers are still essential for higher-value tasks.

4.How do I ensure a smooth transition to automated warehouse solutions?

A: Work with a reputable supplier, provide comprehensive training for staff, and develop a clear implementation plan to ensure a smooth transition.

5.What kind of support and maintenance do automated warehouse solutions require?

A: Regular maintenance and support are crucial to ensure optimal performance. Businesses should expect to invest in ongoing maintenance and support to maximize the benefits of automated warehouse solutions.

Step into the future with SmartlogitecX, a WayZim Technologies venture, reshaping Warehouse Automation in Australia and New Zealand. Our mission is to provide you with advanced, efficient warehouse solutions that are a step ahead. SmartlogitecX combines global tech insights with local market expertise. Ready to upgrade your logistics? Our warehouse automation sales team is on hand to craft your ideal automation strategy.