In today’s fast-paced business environment, efficiency is key to staying competitive. One of the most effective ways to optimize your operations is by implementing a SmartlogitecX automatic conveyor system. These advanced systems are designed to seamlessly transport goods and materials throughout your facility, reducing manual labor and minimizing the risk of errors.

What is an Automatic Conveyor System?

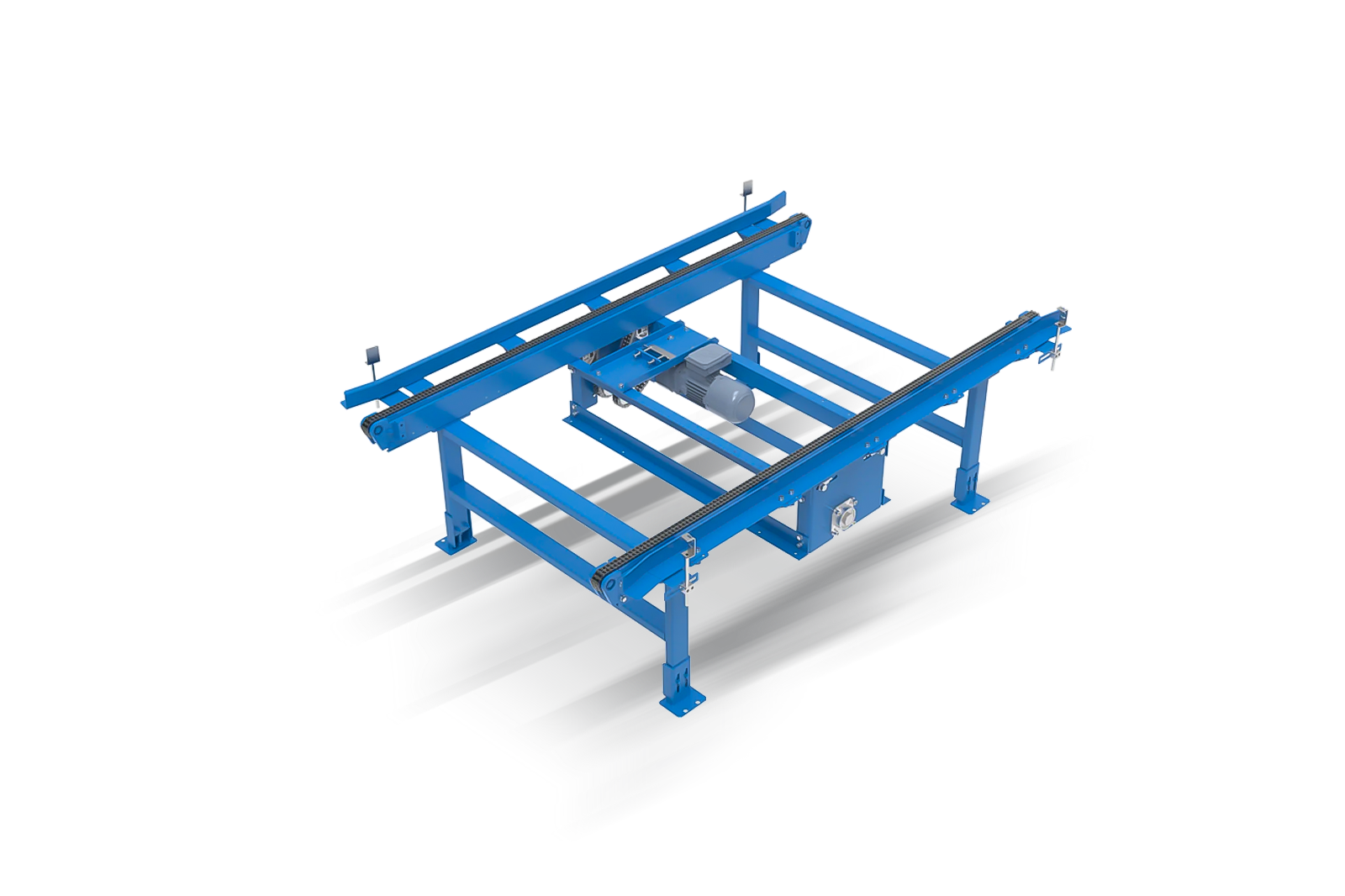

An automatic conveyor system is a mechanical handling apparatus that utilizes a series of belts, rollers, or chains to move products from one location to another without the need for human intervention. These systems are highly customizable and can be tailored to meet the specific needs of your business, whether you’re in manufacturing, distribution, or any other industry that requires the efficient movement of goods.

RELATED: Exploring the Efficiency of Automatic Conveyor Systems

Benefits of Automatic Conveyor Systems

1.Increased Efficiency

One of the primary benefits of an automatic conveyor system is its ability to significantly increase operational efficiency. By automating the transportation of materials, you can reduce the time and effort required to move products throughout your facility, allowing your employees to focus on more value-added tasks.

2.Improved Accuracy

Automatic conveyor systems are designed to operate with a high degree of precision, minimizing the risk of errors that can occur with manual handling. This improved accuracy can help reduce waste, improve quality control, and ultimately lead to higher customer satisfaction.

3.Enhanced Safety

By reducing the need for manual handling of materials, automatic conveyor systems can help create a safer work environment for your employees. These systems can be designed with safety features such as emergency stop buttons, guarding, and sensors to prevent accidents and injuries.

4.Scalability

As your business grows, an automatic conveyor system can easily be expanded or modified to accommodate increased production volumes. This scalability allows you to invest in a system that can grow with your business, providing a long-term solution for your material handling needs.

Types of Automatic Conveyor Systems

There are several types of automatic conveyor systems available, each designed to meet specific operational requirements. Some of the most common types include:

1.Belt Conveyors

Belt conveyors are one of the most versatile and widely used types of automatic conveyor systems. They consist of a continuous loop of belting material that is driven by a motor and supported by rollers or a sliding bed. Belt conveyors are ideal for transporting a wide range of products, from small parts to large packages.

2.Roller Conveyors

Roller conveyors utilize a series of parallel rollers to move products along a fixed path. These systems are often used for heavy-duty applications, such as transporting pallets or large containers. Roller conveyors can be powered by motors or designed to operate using gravity, depending on the specific application.

3.Overhead Conveyors

Overhead conveyors are suspended from the ceiling and are designed to transport products above the working area. These systems are ideal for facilities with limited floor space or for applications that require the movement of products through multiple levels of a building.

Implementing an Automatic Conveyor System

When considering the implementation of an automatic conveyor system, it’s essential to work with an experienced provider who can assess your specific needs and design a customised solution. A well-designed system will take into account factors such as your facility layout, product characteristics, and throughput requirements to ensure optimal performance and efficiency.

RELATED: The Evolution and Benefits of Automated Conveyor Systems in Modern Industries

FAQs

1.What industries can benefit from automatic conveyor systems?

Automatic conveyor systems can benefit a wide range of industries, including manufacturing, distribution, warehousing, food processing, and more.

2.How much maintenance do automatic conveyor systems require?

The maintenance requirements for automatic conveyor systems vary depending on the specific type of system and the operating environment. However, most systems require regular inspections, lubrication, and cleaning to ensure optimal performance and longevity.

3.Can automatic conveyor systems be integrated with other automation technologies?

Yes, automatic conveyor systems can often be integrated with other automation technologies, such as robotics, vision systems, and barcode scanners, to create a fully automated material handling solution.

4.How long does it take to install an automatic conveyor system?

The installation time for an automatic conveyor system depends on the complexity and scale of the project. However, most installations can be completed within several weeks to a few months, depending on the specific requirements.

5.What is the return on investment for an automatic conveyor system?

The return on investment for an automatic conveyor system can vary depending on the specific application and the benefits realized, such as increased efficiency, reduced labor costs, and improved accuracy. However, many businesses find that the long-term benefits of these systems far outweigh the initial investment.

Step into the future with SmartlogitecX, a WayZim Technologies venture, reshaping Warehouse Automation in Australia and New Zealand. Our mission is to provide you with advanced, efficient warehouse solutions that are a step ahead. SmartlogitecX combines global tech insights with local market expertise. Ready to upgrade your logistics? Our sales team is on hand to craft your ideal automation strategy.