In today’s fast-paced market, the efficiency of your supply chain can make or break your business. Among the myriad of advancements, SmartlogitecX automated warehouse solutions have emerged as a cornerstone for enterprises looking to streamline operations and boost productivity. This article explores the transformative impact of automated storage systems and how they can revolutionize your logistics.

The Rise of Automated Warehouse Systems

Automated warehouse systems are more than just a trend; they are a strategic upgrade that integrates sophisticated technologies such as robotics, AI, and machine learning to manage and optimize warehousing functions. These systems offer unparalleled accuracy, speed, and efficiency, drastically reducing human error and labor costs while enhancing order fulfillment speeds and inventory management.

The Role of Robotics in Warehousing

Robotic automation plays a pivotal role in modern warehouses. From autonomous forklifts to drone inventory checkers, robotics ensure that goods are picked, sorted, and transported with precision and speed. This not only improves safety by reducing workplace accidents but also allows human workers to focus on more critical, less repetitive tasks, thus optimizing workforce utilization.

AI and Machine Learning Integration

AI in warehouse management refines predictive analytics, facilitating smarter decision-making. By analyzing data trends, AI predicts future inventory needs, optimizing stock levels and reducing overstocks or stock outs. Machine learning algorithms adapt and improve over time, ensuring continuous enhancement in operational procedures.

Key Benefits of Automated Warehouse Solutions

The shift to automation comes with significant benefits. Here’s how adopting automated warehouse solutions can help your business:

Increased Efficiency and Productivity: Automation speeds up every aspect of warehouse operations, from inventory management to order processing.

Enhanced Accuracy and Reduced Waste: Automated systems minimize human error, ensuring orders are fulfilled correctly the first time.

Cost Reduction: By automating repetitive tasks, companies can reduce labor costs and minimize the likelihood of expensive errors.

Scalability: Automated systems can be scaled easily to accommodate growth, a crucial advantage in rapidly changing markets.

Improved Worker Safety: Reducing human involvement in potentially hazardous areas of warehouse operations lowers the risk of accidents.

RELATED: Automated Warehouse Solutions: Streamlining Operations for Efficiency and Productivity

Implementing Automated Storage and Retrieval Systems (ASRS)

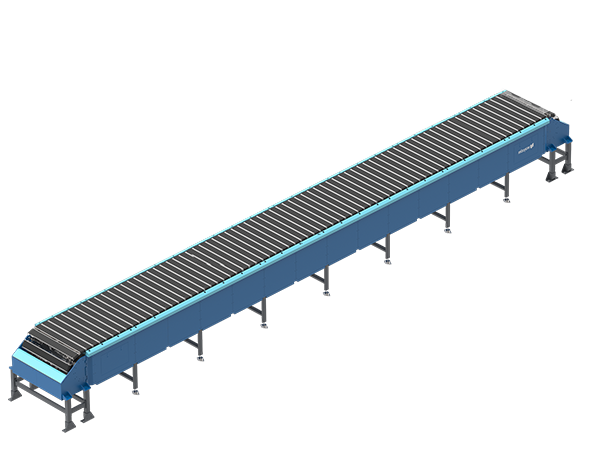

Implementing an ASRS can be transformative. These systems, like the SmartlogitecX AS/RS pallet stacker crane, use compact storage solutions to maximize space usage and automate the retrieval of goods. The pallet stacker crane uses pallets as the access unit and has incomparable advantages in meeting the performance indexes such as height, weight, and throughput of cargo access. It is one of the most important types of equipment for overhead heavy-duty stereo warehouse widely use in fresh food, cold chain, food, medicine, manufacturing, automobile, furniture, military industry, and new energy. When integrated with warehouse management software, an ASRS can dramatically increase the volume of goods processed, making it an ideal solution for businesses looking to expand their operations without additional square footage.

Choosing the Right Automated Warehouse Provider

Selecting the right provider is crucial. Look for companies that offer comprehensive solutions, including hardware like sorting robots and software suites that offer real-time analytics. Ensure they have a robust support system and a track record of successful implementations.

FAQs About Automated Warehouse Solutions

1.What are automated warehouse solutions?

Automated warehouse solutions involve the use of technology such as robotics, AI, and automated storage and retrieval systems to enhance the efficiency and effectiveness of warehouse operations.

2.How do automated warehouse solutions improve efficiency?

These systems streamline various warehouse tasks, reduce manual labor by automating repetitive tasks, and enhance accuracy in order fulfillment. This leads to faster processing times and lower operational costs.

3.Are automated warehouse solutions cost-effective?

Yes, while the initial setup for automated warehouse solutions can be significant, the long-term savings in labor, improved efficiency, and lower error rates make these solutions highly cost-effective.

4.Can small to medium enterprises benefit from automated warehouses?

Absolutely! Automated systems can be scaled and customized to fit the needs of smaller operations, allowing SMEs to compete more effectively in the market by boosting their fulfillment capabilities.

5.What should I consider when choosing an automated warehouse solution?

Focus on solutions that integrate seamlessly with your existing operations and can scale as your business grows. Consider the reliability of the technology, the provider’s industry experience, and the level of customer support provided.

By embracing automated warehouse solutions, companies can significantly enhance their operational efficiency and position themselves strongly for future growth. This technological leap might just be the catalyst needed to elevate your logistics to the next level.

Step into the future with SmartlogitecX, a WayZim Technologies venture, reshaping Warehouse Automation in Australia and New Zealand. Our mission is to provide you with advanced, efficient warehouse solutions that are a step ahead. SmartlogitecX combines global tech insights with local market expertise. Ready to upgrade your logistics? Our sales team is on hand to craft your ideal automation strategy.