In the age of instant gratification and same-day delivery, logistics companies are under immense pressure to streamline their operations. Enter automated sortation systems—the robotic orchestra conductors of the modern warehouse, revolutionizing how parcels get from A to B. In 2024, their impact on efficiency will reach a crescendo, transforming the once chaotic dance of products into a precisely choreographed ballet.

RELATED: The Evolution of Automated Sortation Systems.

Ditching the Deluge: From Manual Mayhem to Algorithmic Accuracy

Imagine a warehouse floor teeming with workers, sprinting between towering shelves, eyes frantically scanning barcodes. Mispicks abound, deliveries are delayed, and frustration hangs heavy in the air. This outdated manual sorting method is not only inefficient but also prone to errors and costly human fatigue.

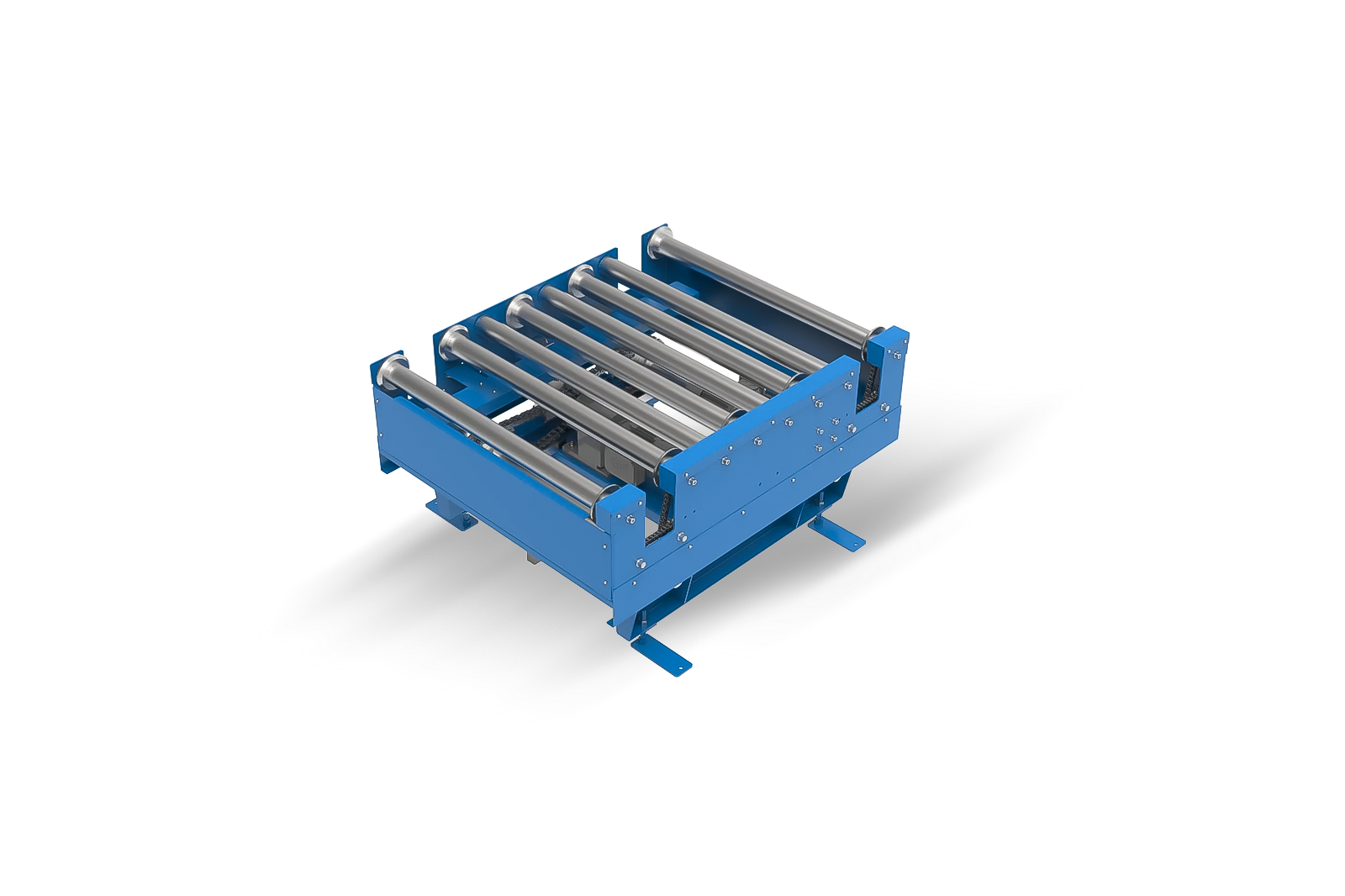

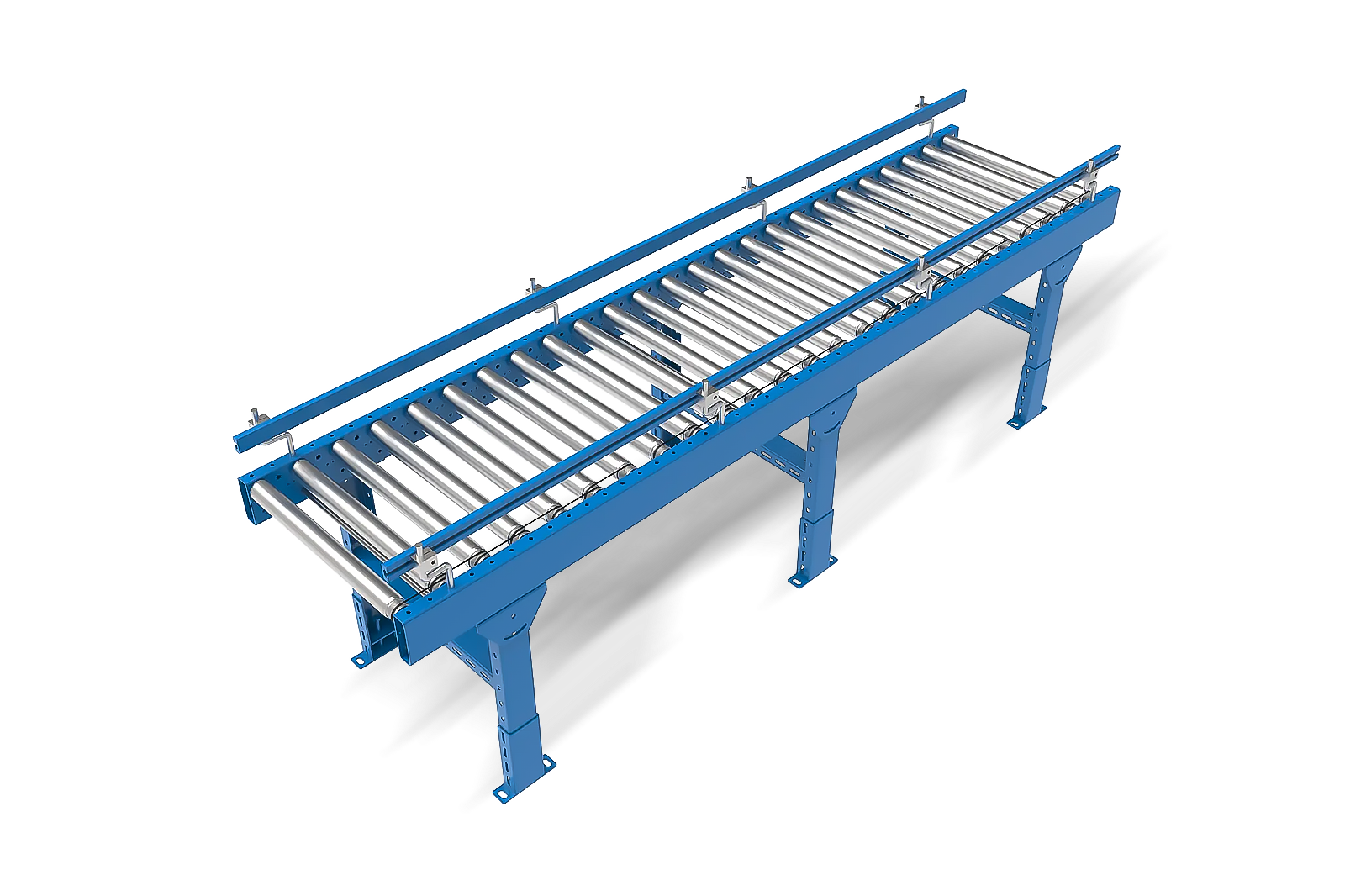

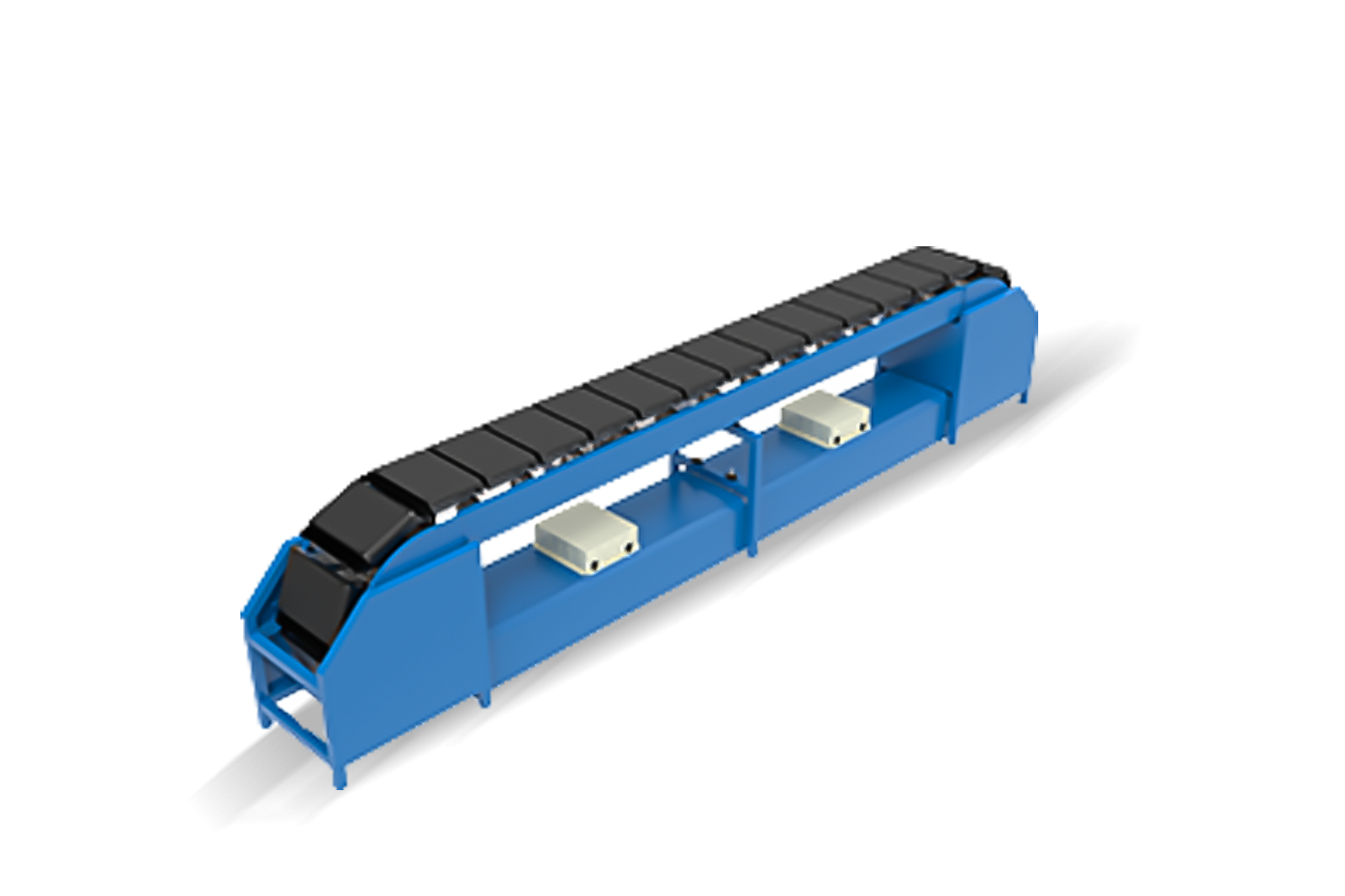

Automated sortation systems replace this frantic scramble with the steady hum of technology. From conveyor belts to high-speed sorters and robotic arms, these systems leverage barcode scanners, RFID tags, and artificial intelligence to identify, track, and route packages with laser precision. The result? A dramatic reduction in errors, faster order fulfillment, and a workforce unleashed from tedious tasks to focus on higher-value activities.

The Efficiency Symphony: A Multitude of Benefits in Harmony

The benefits of automated sortation go beyond mere speed.

1.Boosting Throughput:

Imagine processing orders twice as fast! That’s the reality with automated systems, enabling warehouses to handle increased demand without breaking a sweat.

2.Accuracy Amplified:

Mispicks plummet when robots handle the sorting, minimizing customer frustration and costly returns.

3.Cost-Cutting Cadence:

While the initial investment might seem daunting, long-term savings on labor, reduced errors, and increased productivity make automated systems a cost-effective symphony.

4.Space Optimization:

These systems can work wonders in optimizing warehouse layout, maximizing storage capacity, and making every inch count.

5.Employee Empowerment:

With robots taking over the repetitive tasks, human workers are freed to focus on strategic planning, quality control, and customer service, elevating their value and job satisfaction.

Schedule a Call with SmartlogitecX

The 2024 Twists: AI Takes the Lead

In 2024, the efficiency symphony gets even more sophisticated with the integration of artificial intelligence. AI-powered sortation systems learn from historical data, anticipate peak times, and dynamically adjust sorting algorithms in real-time. This adaptive intelligence optimizes resource allocation, further minimizing downtime and maximizing efficiency.

The Future of Flow: Beyond 2024

As technology advances, the boundaries between automated sortation and other warehouse functionalities are blurring. We can expect:

1.Integration with inventory management systems:

Real-time inventory data will guide sorting decisions, preventing overstocking and understocking.

2.Robotic collaboration:

Seamless communication between sorting robots and autonomous picking robots will create a fully automated fulfillment ecosystem.

3.Personalization in the pipeline:

Sortation systems will be able to prioritize and route packages based on individual customer preferences or delivery urgency.

The future of warehousing is undeniably automated, and sortation systems play a critical role in this paradigm shift. By embracing this technological wave, logistics companies can not only survive the ever-increasing demand but also thrive, delivering a symphony of efficiency that resonates with customers and competitors alike.

RELATED: Automated Sortation Systems: Revolutionising Logistics with SmartLogitecx.

Step into the future with SmartlogitecX, a WayZim Technologies venture, reshaping Warehouse Automation in Australia and New Zealand. Our mission is to provide you with advanced, efficient warehouse solutions that are a step ahead. SmartlogitecX combines global tech insights with local market expertise. Ready to upgrade your logistics? Our sales team is on hand to craft your ideal automation strategy.