In the fast-paced world of e-commerce and logistics, efficiency and accuracy are paramount. At SmartLogitecX, we understand the critical role that express parcel sorting systems play in streamlining operations and ensuring customer satisfaction. Our cutting-edge solutions, powered by advanced technology and intelligent automation, enable businesses to handle high volumes of parcels with unparalleled speed and precision.

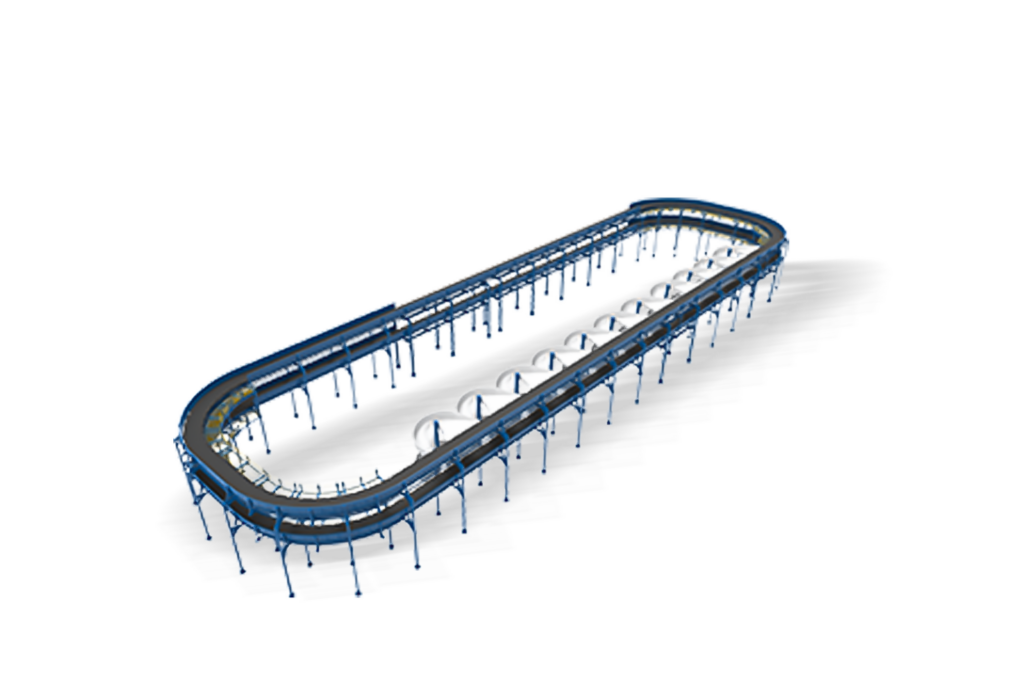

Cross Belt Sorting System: The Ultimate in Efficiency

SmartlogitecX Cross Belt Sorting System is the cornerstone of our express parcel sorting capabilities. With a sorting accuracy of up to 99.99% and a running rate of up to 3.2 m/s, this system is designed to handle even the most demanding logistics challenges. At the heart of the system are 2D bulk flow singulators and 6-sided barcode readers for large parcels, which ensure optimal performance in terms of running stability, sorting efficiency, sorting accuracy, and running noise.

RELATED: Automated Parcel Sorting Systems: Revolutionising Logistics

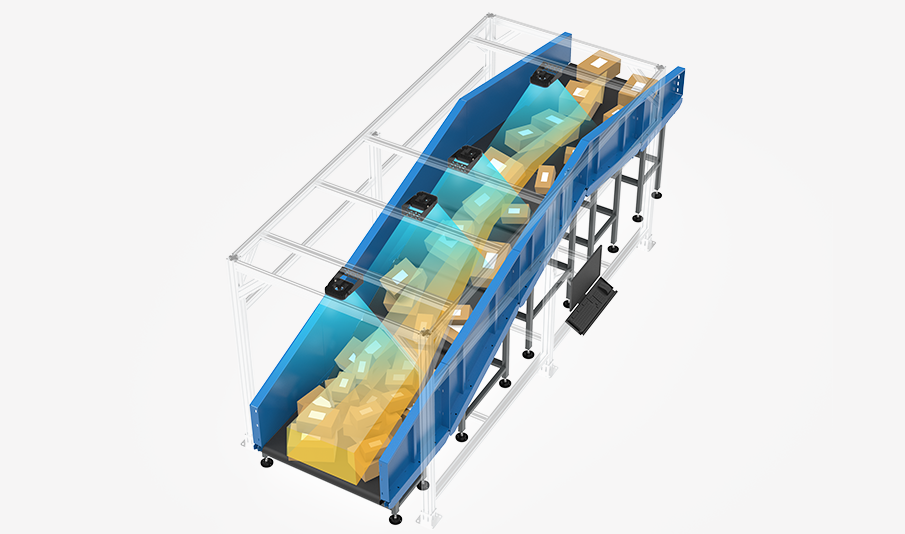

3D Bulk Flow Singulator: Intelligent Parcel Handling

The 3D Bulk Flow Singulator is a game-changer in parcel sorting technology. By combining an intelligent control system with advanced algorithms, this equipment can accurately control the quantity of parcels in each infeed section and singulate a mass of stacked parcels. This innovative approach eliminates parcel overlapping and bumping, ensuring a smooth and efficient infeed process that significantly improves overall sorting efficiency.

2D Bulk Flow Singulator: Seamless Barcode Scanning

Our 2D Bulk Flow Singulator is designed to streamline the barcode scanning process, a critical step in accurate parcel sorting. The equipment obtains parcel barcode information and uploads it to the management system, allowing for seamless tracking and routing. Once the barcodes are scanned, the parcels are conveyed to the pivot wheel sorter for efficient sorting and distribution.

Automated Infeed System: Leveraging Deep Learning

The Automated Infeed System is a testament to our commitment to leveraging cutting-edge technology for optimal performance. By utilizing instance segmentation based on a deep learning network and a three-dimensional spatial point cloud algorithm, this system calculates the spatial location information of parcels, enabling full-time and efficient pickup. This automated approach minimizes manual intervention and ensures a smooth and reliable infeed process.

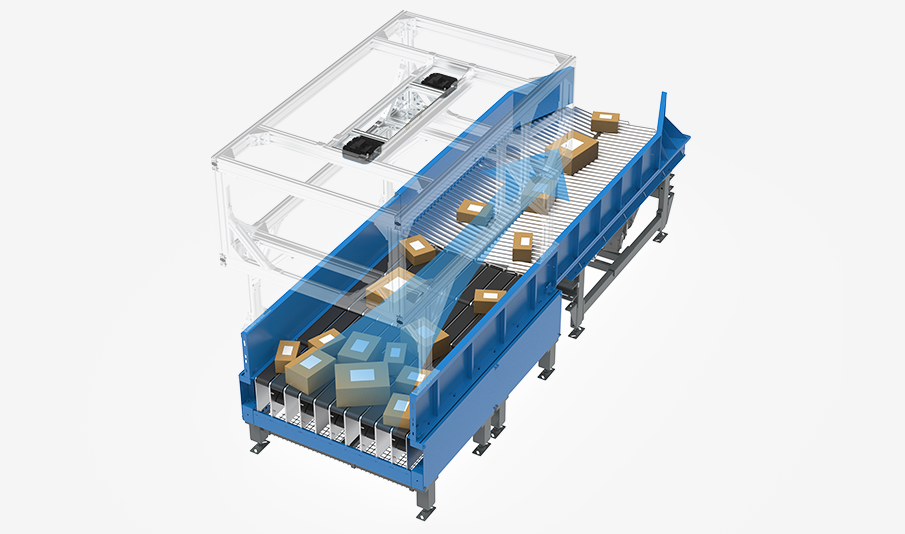

DWS System: Real-Time Data Collection

Accurate data collection is essential for effective parcel sorting, and our DWS System is up to the task. Equipped with Wayzim’s high-resolution intelligent barcode reading cameras, volumetric meters, and dynamic weighing modules, this system efficiently collects and outputs crucial information such as barcode data, volume, and weight in real-time. This comprehensive data collection enables precise tracking and reporting throughout the sorting process.

Position Detection System: Ensuring Accuracy

The SmartlogitecX Position Detection System is a comprehensive solution that integrates multiple detection capabilities to ensure accurate parcel sorting. This system combines parcel center position detection, edge detection, detection of one carrier with multi-parcel, offset correction detection, and empty pallet detection. By outputting express parcel dimensions and position information and correcting offset express parcels, this system maintains the highest levels of sorting accuracy and efficiency.

RELATED: How Automated Sortation Systems Streamline Your Logistics

Frequently Asked Questions

1.What is an express parcel sorting system?

An express parcel sorting system is an automated solution designed to efficiently sort and route parcels based on their destination, ensuring fast and accurate delivery.

2.How does the Cross Belt Sorting System achieve high sorting accuracy?

The Cross Belt Sorting System achieves high sorting accuracy through the use of 2D bulk flow singulators and 6-sided barcode readers for large parcels, which ensure optimal performance and minimize errors.

3.What are the benefits of using a 3D Bulk Flow Singulator?

The 3D Bulk Flow Singulator improves sorting efficiency by accurately controlling the quantity of parcels in each infeed section and singulating stacked parcels, preventing overlapping and bumping.

4.How does the Automated Infeed System utilize deep learning?

The Automated Infeed System uses instance segmentation based on a deep learning network and a three-dimensional spatial point cloud algorithm to calculate parcel spatial location information, enabling efficient and automated pickup.

5.What information does the DWS System collect in real-time?

The DWS System collects crucial information such as barcode data, volume, and weight in real-time using high-resolution intelligent barcode reading cameras, volumetric meters, and dynamic weighing modules.

Step into the future with SmartlogitecX, a WayZim Technologies venture, reshaping Warehouse Automation in Australia and New Zealand. Our mission is to provide you with advanced, efficient warehouse solutions that are a step ahead. SmartlogitecX combines global tech insights with local market expertise. Ready to upgrade your logistics? Our sales team is on hand to craft your ideal automation strategy.