Inefficient sheet metal storage costs Australian fabricators more than most realise. Floor space consumed by horizontal racking, time lost searching through stacked panels, and material damage from forklift handling all erode margins that are already under pressure. In workshops across Melbourne, Sydney, and Brisbane, the same pattern repeats: sheets piled on cantilever racks or stacked on the floor, accessed by overhead cranes or forklifts, managed by memory and guesswork.

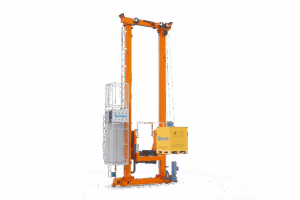

Automated tower storage systems offer a fundamentally different approach. These SmartlogitecX vertical lift modules store panels and sheet metal in indexed trays within a compact tower, delivering materials directly to the operator at ground level. No forklifts. No manual searching. No wasted square metres.

SmartlogitecX supplies and configures these systems for Australian fabricators, steel processors, and panel manufacturers. This guide explains how the technology works, what operational advantages it delivers, and how to evaluate the right configuration for your facility.

How Automated Tower Storage Systems Work

Core Components and Vertical Lift Mechanism

A tower storage system consists of a steel frame housing multiple trays stacked vertically, a motorised lift that moves trays between storage positions and an access opening, and a PLC controller that manages tray indexing and retrieval commands. The operating principle is goods-to-person: rather than an operator navigating a warehouse with a forklift, the system brings the required sheet directly to the operator at an ergonomic working height.

The lift operates within the tower’s central column. When an operator requests a specific material via the control panel or connected software, the PLC identifies the correct tray, retrieves it, and delivers it to the access bay. The entire cycle typically completes in under 60 seconds.

Material Types and Load Specifications

Tower systems accommodate a broad range of flat materials. Steel, aluminium, stainless steel, copper, composite panels, timber sheets, and plastic are all standard. Tray configurations vary by manufacturer, but typical capacities range from 1,500 kg to 3,000 kg per tray. Standard sheet sizes supported include 3000×1500 mm, 4000×2000 mm, and 6000×2500 mm, with custom tray dimensions available for non-standard stock.

Trays are built with either solid sheet-metal bottoms for lighter materials or reinforced latticed steel bottoms for heavier loads such as bundled bar stock and thick plate. Mobile load-securing supports prevent material shifting during handling.

Software Integration and Inventory Control

Modern tower systems connect directly with SmartlogitecX warehouse management systems (WMS), enterprise resource planning (ERP) platforms, and manufacturing execution systems (MES). This integration enables real-time inventory visibility. Every sheet stored, retrieved, or consumed is tracked automatically, eliminating the manual stock counts and spreadsheet-based systems that many Australian fabricators still rely on.

For operations running platforms such as JobBOSS, MYOB Advanced, or SAP Business One, this connectivity means production planning can draw on accurate, live material data rather than estimates.

Five Operational Advantages for Australian Fabricators

1. Floor Space Recovery and Warehouse Footprint Reduction

This is the most immediately quantifiable benefit. A single tower system with a footprint of roughly 23 square metres can store the equivalent material volume that would otherwise require several hundred square metres of floor-level racking and forklift aisle space. With industrial lease rates in Australian capital cities ranging from $90 to $180 per square metre annually, the floor space recovered translates directly into cost savings or additional production capacity.

2. Faster Retrieval Times and Production Continuity

Manual sheet retrieval using forklifts or overhead cranes introduces delays at every job changeover. Operators search for the correct material, manoeuvre equipment into position, and transport sheets to the cutting station. With an automated tower, retrieval is initiated via the control interface and completed within a minute. For fabricators feeding CNC punch presses or fibre laser cutters, this reduction in changeover time keeps machines running and supports lean production schedules.

3. Workplace Safety and WHS Compliance

Sheet metal handling is one of the higher-risk activities in fabrication workshops. Crush injuries from falling sheets, musculoskeletal strain from manual lifting, and forklift-related incidents are well-documented. Automated tower systems eliminate the need for forklift retrieval entirely and deliver materials at ergonomic height, reducing both acute injury risk and long-term strain. For Australian operations, this supports compliance with Work Health and Safety (WHS) obligations and can positively affect workers’ compensation premiums.

4. Reduced Material Damage and Waste

Sheets stored horizontally on cantilever racks or stacked on the floor are exposed to scratching, warping, moisture, and contamination. Every damaged sheet is written off or downgraded, eating directly into material budgets. Tower systems store each sheet in a dedicated tray within an enclosed structure, protecting surfaces from contact damage and environmental exposure. For fabricators working with pre-finished or coated panels, this protection alone can justify the investment.

5. Tighter Inventory Accuracy and Stock Visibility

Manual inventory systems in sheet metal operations are notoriously unreliable. Miscounted stock leads to over-ordering, production delays when materials are unexpectedly depleted, and dead stock occupying valuable storage positions. With every tray indexed and every retrieval logged automatically, a tower system delivers real-time stock visibility. Purchasing decisions are based on actual inventory data rather than estimates, reducing both excess stock and emergency procurement costs.

Choosing the Right Tower Storage Configuration

Single-Tower vs. Double-Tower Systems

Single-tower systems suit mid-volume fabricators who need organised storage and automated retrieval without the complexity of dual-zone operations. Double-tower configurations are designed for higher-throughput environments. They allow separation of loading and unloading zones, meaning fresh stock can be loaded into one tower whilst production draws from the other. This eliminates bottlenecks in operations where material turnover is constant.

Indoor, Outdoor, and Hybrid Installation Options

Not every facility has the internal ceiling height or spare floor space to accommodate a tower system indoors. Weatherproofed outdoor models extend storage vertically outside the building envelope, with the access bay positioned at the interior wall. This is particularly relevant for Australian operations in older industrial estates where internal space is limited. Climate-rated enclosures handle the temperature extremes and coastal conditions common across Australian regions.

Scalability and Modular Expansion

Tower height can typically be extended after initial installation, and additional towers integrated into existing workflows as throughput grows. SmartlogitecX advises Australian businesses on selecting the right configuration for their current operational footprint and throughput requirements, with a clear upgrade path built into the initial design.

Integration with CNC, Laser Cutting, and Production Lines

Automated Feed to Processing Machines

Where tower systems deliver the greatest production impact is in their connection to downstream processing equipment. Shuttle systems and conveyors link the tower’s access bay directly to CNC punch presses, fibre laser cutters, and plasma tables. Sheets move from storage to the machine bed without manual transport. This creates a continuous material flow that reduces idle machine time and supports unattended or lightly attended production runs.

Managing Mixed-Material Workflows

Most fabrication shops work with multiple material types, grades, and thicknesses simultaneously. A tower system stores each material in a dedicated, indexed tray, so switching between jobs requires only a retrieval command rather than physically restacking inventory. SmartlogitecX supplies systems that integrate with the CNC and laser cutting equipment most commonly deployed in Australian fabrication workshops, ensuring compatibility from day one.

Return on Investment and Total Cost of Ownership

Calculating Space and Labour Savings

ROI on a tower storage system stems from several measurable factors: recovered floor space (valued at local lease rates), reduced forklift operations and associated fuel and maintenance costs, lower labour requirements (a single operator replaces the two to three people typically needed for manual sheet handling), and reduced material damage from handling and exposure. For a mid-sized Australian fabricator, combined annual savings frequently exceed $150,000. SmartlogitecX provides detailed ROI modelling and total cost of ownership assessments as part of its consultative process for prospective clients.

Long-Term Durability and Maintenance Requirements

These systems are engineered for industrial longevity. Robust welded-steel construction, PLC-controlled servo motors, and chain-drive lift mechanisms deliver reliable operation over decades of continuous use. Scheduled maintenance is straightforward and predictable, with most systems requiring only periodic lubrication, sensor calibration, and software updates. Unplanned downtime is rare when preventive maintenance schedules are followed.

Frequently Asked Questions

1. How much floor space can an automated tower storage system save?

A typical tower system reduces the storage footprint by up to 80%, consolidating hundreds of square metres of horizontal racking into approximately 23 square metres of floor space.

2. What types of sheet metal and panels can a tower system store?

Tower systems store steel, aluminium, stainless steel, copper, composite panels, timber sheets, and plastics. Tray configurations accommodate standard and custom sheet sizes.

3. How does an automated tower system improve workplace safety?

The system eliminates forklift-dependent retrieval and delivers materials at ergonomic height. This reduces crush injuries, manual lifting strains, and forklift-related incidents.

4. Can tower storage systems integrate with CNC and laser cutting machines?

Yes. Shuttle systems and conveyors connect the tower directly to CNC punch presses, fibre laser cutters, and plasma tables for continuous automated material feed.

5. What is the typical load capacity per tray in a tower storage system?

Tray capacities range from 1,500 kg to 3,000 kg depending on the system configuration and tray type, accommodating both standard and heavy-gauge materials.

6. How many operators are required to run an automated sheet storage tower?

A single operator can manage all storage and retrieval operations via the PLC control interface, replacing the two to three people typically needed for manual handling.

7. Can the tower be expanded after initial installation?

Yes. Most tower systems are modular. Height can be extended and additional towers integrated into existing workflows as production volumes grow.

8. What software systems does an automated tower storage system connect with?

Tower systems integrate with WMS, ERP, and MES platforms including JobBOSS, MYOB Advanced, SAP Business One, and similar systems for real-time inventory tracking.

Streamline Your Sheet Metal Storage with SmartlogitecX

For Australian fabricators and manufacturers operating under the twin pressures of rising industrial costs and tightening safety obligations, automated tower storage is not a luxury. It is a practical response to measurable operational problems. The maths is straightforward: recovered floor space, faster material access, reduced labour dependency, fewer workplace incidents, and tighter inventory control.

Whether you operate a single laser cutting cell or a multi-machine production facility, the right tower configuration exists to match your throughput, your materials, and your available footprint.

SmartlogitecX offers site assessments, configuration consultations, and detailed ROI estimates for Australian operations considering automated tower storage. Contact the team to discuss your requirements and take the first step toward a smarter, safer, and more productive storage system.