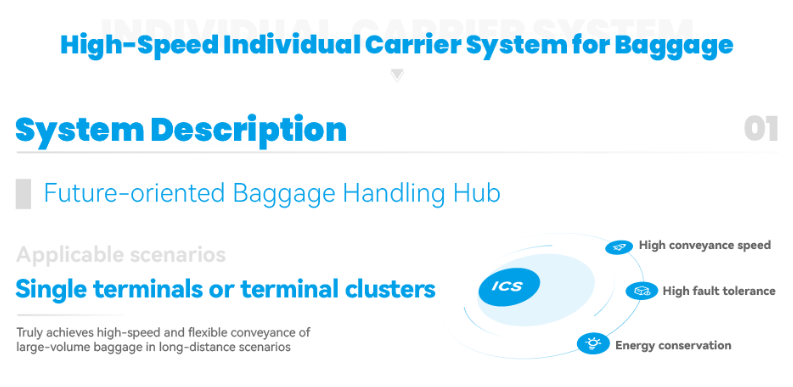

With the continuous growth of global air transport, baggage handling systems are facing unprecedented challenges. Traditional baggage handling systems have issues such as low sorting efficiency, mis-sorting, and damage in high-speed, high-density, and long-distance baggage sorting scenarios unlike SmartlogitecX baggage handling systems.

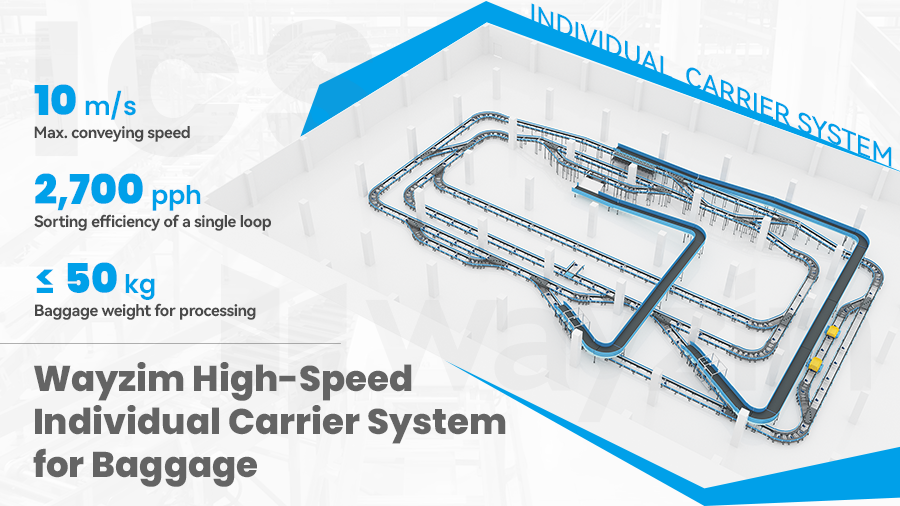

Leveraging its deep technical expertise in intelligent logistics, Wayzim has developed the High-Speed Individual Carrier System (ICS) for Baggage, which solves the baggage transfer and sorting problems between large hub airport terminals. The system, based on the precise control concept of “one pallet for one piece of baggage”, achieves single-piece management, efficient distribution, and flexible scheduling, reshaping the future airport baggage handling systems.

Additionally, the ICS system is highly scalable. It can be optionally paired with an Early Baggage Storage (EBS) system to ensure seamless operation, enabling the storage, retrieval, and dispatch of bulk or single-piece baggage.

1. Full-process tracking, safe and reliable

Each piece of baggage corresponds to a pallet, ensuring 100% full-process tracking to avoid mis-sorting, loss, or damage.

2. High-speed conveyance with leading efficiency

Conveyance speed can reach 10 m/s, enabling long-distance baggage conveyance at a high speed.

3. Modular design and flexible layout

The system uses a modular design, facilitating quick installation and maintenance. The system is simple in structure and flexible in layout.

4. Information-driven intelligent scheduling

Optimal resource allocation and minimized energy consumption are achieved through the dynamic task allocation and path planning of the system control platform.

The core of the ICS system lies in the independent control of intelligent pallets and the path planning of the track system. Baggage loaded at the front end is automatically bound to a unique pallet, and the optimal route is assigned by the high-level control system. The pallets run autonomously on the track based on the specified logic, with support for intelligent obstacle avoidance, scheduling, merging, and diverting.

The system dynamically adjusts flow and cycle time through a combination of routing algorithms and dynamic simulation, ensuring smooth operation even during peak hours. The empty pallet transporting system (ETS) used before top loading is designed with cross-lines for exchanging empty pallets. If one supply line in the ETS continues to fail, the empty pallets at the top loading station can be replenished by another supply line, providing high redundancy and fault tolerance and enhancing the overall system’s stability and availability.

Reconstructing the intelligent path of baggage handling

The Wayzim ICS is not only an upgrade to traditional sorting systems but also a key hub technology in the construction of intelligent airports. As an intelligent baggage handling solution for future airport scenarios, the ICS is reconstructing the entire logic of baggage sorting and empowering global aviation hubs to move towards a new round of efficiency revolution with its leading technical architecture and outstanding performance.