Australian warehouse operators face a convergence of pressures that manual processes can no longer absorb: rising labour costs, accelerating order volumes driven by e-commerce growth, and fulfilment windows that continue to shrink. Automated storage systems offer the most direct and measurable response to each of these challenges.

Intralogistics — the management of internal material flows within a facility, from receiving through to dispatch — represents the operational backbone of every warehouse. When that backbone is automated, throughput increases, errors decline, and labour is redirected toward higher-value tasks.

SmartlogitecX works with various global suppliers in warehouse automation products engineered for Australian operating conditions. This guide examines the core system types, selection criteria, ROI considerations, and implementation guidance that warehouse decision-makers need to evaluate before committing to an automation investment.

What Are Automated Storage Systems in Intralogistics?

Defining Intralogistics and Where Automation Fits

Intralogistics encompasses every internal material-handling stage: receiving, storage, picking, packing, and dispatch. Each stage introduces potential bottlenecks when managed manually. Automated storage systems address these friction points by replacing repetitive, error-prone human tasks with precisely controlled mechanical and software-driven processes. The result is a facility where materials move predictably, inventory accuracy remains consistently high, and throughput scales without proportional increases in headcount.

Core Components of an Automated Storage System

A functional automated storage system comprises several interdependent elements: purpose-built storage structures (racking, shelving, or tray systems), retrieval mechanisms (cranes, shuttles, or robotic extractors), conveyor integration for material transport, a warehouse management system (WMS) that orchestrates inventory logic, and control systems that govern machine movements in real time. Each component must be specified to match the facility’s throughput targets and SKU profile.

Why Australian Warehouses Are Adopting Automation Now

Several market-specific forces are accelerating adoption. Chronic workforce shortages in logistics roles, particularly across Sydney, Melbourne, and Brisbane corridors, make it increasingly difficult to staff warehouses reliably. E-commerce volumes continue to grow, demanding faster and more accurate fulfilment. Meanwhile, industrial real estate costs in major distribution hubs are rising, placing a premium on storage density. SmartlogitecX warehouse automation delivers measurable advantages across all three dimensions — reducing labour dependency, increasing throughput, and extracting maximum value from existing floor space.

Types of Automated Storage and Retrieval Systems

Unit-Load and Miniload AS/RS

Unit-load AS/RS handle full pallets, making them well suited to high-volume bulk storage and distribution environments. Miniload AS/RS operate at tote, carton, and small-item level, serving facilities where order profiles require frequent, granular picks. Both system categories rely on crane-based or shuttle-based retrieval, and the choice between them depends on the dominant unit of handling within the operation.

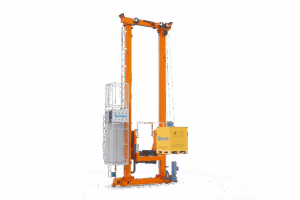

Vertical Lift Modules and Vertical Carousels

SmartlogitecX vertical lift modules (VLMs) use an enclosed structure with an inserter/extractor mechanism to store and retrieve trays of goods on demand. They maximise vertical space, dramatically reduce the physical footprint required for small-parts storage, and improve pick accuracy by presenting items directly to the operator. Vertical carousels operate on a rotating-shelf principle, offering high-speed retrieval for environments where throughput density is critical. Both solutions suit facilities with limited floor space but available ceiling height.

Shuttle Systems and Goods-to-Person Solutions

Pallet shuttle systems and goods-to-person (GTP) technologies represent the next step in warehouse automation maturity. Shuttle systems use autonomous carriers within racking lanes to move pallets without requiring full-aisle crane access, enabling higher lane density and faster cycle times. GTP solutions bring inventory to a stationary operator, eliminating travel time and significantly boosting pick rates. SmartlogitecX’s product range includes shuttle and GTP configurations designed for Australian warehouse specifications.

Key Benefits of Automating Warehouse Storage

Increased Storage Density and Space Utilisation

Automated storage systems can improve storage density by 40–60% compared to conventional selective racking. This is achieved through tighter aisle spacing (or aisle elimination in shuttle-based systems), vertical space exploitation, and intelligent slotting algorithms that allocate positions based on item dimensions and velocity. For Australian operators facing rising lease costs per square metre, this density gain translates directly into cost savings or deferred facility expansion.

Faster Throughput and Order Accuracy

Facilities deploying AS/RS and GTP technologies typically report significant increases in picks per hour alongside order accuracy rates exceeding 99.9%. Reduced error rates lower return-processing costs and improve customer satisfaction metrics, both of which contribute to stronger downstream revenue performance.

Labour Efficiency and Workplace Safety

Automation reduces the volume of repetitive manual tasks — lifting, walking, and reaching — that contribute to workplace injuries. By reassigning staff from low-value material handling to supervisory, quality-control, and exception-management roles, warehouses improve both productivity per head and employee retention.

How to Choose the Right Automated Storage System

Assessing Your Warehouse Profile and SKU Mix

Before selecting a warehouse management system, operators should document their facility dimensions, ceiling heights, SKU characteristics (size, weight, fragility), order profiles (single-line vs multi-line, batch vs wave), and peak throughput requirements. This operational baseline determines which system architecture delivers the best fit.

Integration With Existing Warehouse Management Systems

Seamless data exchange between the automated storage hardware and the existing WMS is non-negotiable. Operators need to verify API compatibility, data-flow architecture, and whether the automation vendor supports the WMS platforms already deployed. Poor integration creates information silos that undermine the efficiency gains automation is intended to deliver.

Scalability and Future-Proofing Your Investment

Modular system design allows operators to expand capacity incrementally as throughput demands grow, rather than committing to oversized infrastructure from day one. SmartlogitecX designs automation solutions with long-term scalability at their core, ensuring that initial investments continue to deliver returns as operations evolve.

ROI and Investment Considerations for Warehouse Automation

Understanding Total Cost of Ownership

The total cost of ownership for an automated storage system extends beyond the capital outlay. Decision-makers should account for installation and commissioning, ongoing maintenance contracts, software licensing and updates, energy consumption, and staff training. System costs vary significantly based on complexity, throughput capacity, and the degree of customisation required.

Measuring Payback Period and Operational Savings

ROI calculations should incorporate four primary savings categories: labour cost reduction, error-related cost elimination, throughput-driven revenue gains, and space savings (deferred expansion or reduced lease costs). Most warehouse automation projects in Australia achieve payback within two to five years, depending on system type, operational scale, and the baseline efficiency of the facility prior to automation.

Frequently Asked Questions

1. What is an automated storage and retrieval system (AS/RS)?

An AS/RS is a technology-driven system that automatically places and retrieves loads from defined storage locations. It typically comprises storage structures, mechanical retrieval devices, and software controls that manage inventory movement without manual intervention.

2. How much do automated storage systems cost in Australia?

Costs vary widely based on system type, scale, and complexity. Small vertical lift module installations may start from $150,000, while large-scale AS/RS implementations can exceed $2 million. A detailed site assessment is essential for accurate costing.

3.What types of warehouses benefit most from intralogistics automation?

Facilities with high SKU counts, rapid order cycles, limited floor space, or significant labour challenges benefit most. E-commerce fulfilment centres, pharmaceutical distribution hubs, and cold-chain operations are common adopters.

4. How long does it take to implement an automated storage system?

Implementation timelines range from three to twelve months depending on system complexity, site preparation requirements, and WMS integration scope.

5. Can automated storage systems integrate with my existing WMS?

Most modern AS/RS and shuttle systems are designed with open API architectures that support integration with leading WMS platforms. Compatibility should be confirmed during the vendor evaluation stage.

6. What maintenance do automated storage systems require?

Routine maintenance includes mechanical inspections, software updates, sensor calibration, and conveyor servicing. Most vendors offer scheduled maintenance contracts to ensure system uptime.

7.What is the difference between goods-to-person and person-to-goods systems?

In goods-to-person systems, inventory is delivered to a stationary operator, eliminating travel time. Person-to-goods systems require operators to walk to storage locations to retrieve items. Goods-to-person systems generally achieve higher pick rates and lower error rates.

8. How does SmartlogitecX support warehouse automation projects?

SmartlogitecX provides end-to-end support including site assessment, system design, product supply, installation, WMS integration, and ongoing maintenance for Australian warehouse operations.

Build a More Efficient Warehouse With Automated Storage

Automated storage systems are no longer reserved for enterprise-scale operations. They are accessible, modular, and increasingly essential for any Australian warehouse seeking to remain competitive as order volumes rise and labour availability tightens. The critical decisions involve matching system type to operational profile, verifying WMS integration, and building a realistic total-cost-of-ownership model before committing capital.

SmartlogitecX offers a full range of warehouse automation products purpose-built for Australian facilities. To explore available systems or request a tailored automation assessment, visit the SmartlogitecX warehouse automation products page or contact the team for a consultation.