In the age of rapid technological advancements, airport automation has emerged as a cornerstone of the aviation industry’s efforts to enhance efficiency and passenger experience. From automated check-in kiosks to advanced security screening and self-boarding gates, automation is revolutionizing the way airports function. Central to this transformation is the automation of baggage handling through state-of-the-art conveyor systems.

Airport conveyor systems play a crucial role in modern air transportation. They not only ensure that passengers’ luggage is accurately delivered to the designated destination but also significantly improve overall airport operational efficiency and reduce passenger wait times. So, how exactly are the airport conveyor systems designed and operated?

The conveyor system includes two types of conveying modes: linear conveyor system and diverting/merging system. The linear conveyor system is primarily used for horizontal luggage transport, while the diverting/merging system meets the requirements for merging and diverging tasks in airport luggage handling systems, thereby reducing conveyor pressure. Both systems can be flexibly configured based on building spatial structures and operational needs.

Conveyor System—Smooth transport & Accurate tracking

The conveyor system is the vital network of an automated baggage handling system. It comprises horizontal conveyors, slope conveyors, curved conveyors, and diverging/merging conveyors. Wayzim’s efficient and stable conveying system can quickly and accurately transport baggage, solving the low efficiency, high energy consumption, and item loss problems of traditional conveyors.

The linear conveying system is a combination of horizontal conveyor and slope conveyor, which realizes the baggage conveying in the linear horizontal direction. The conveyor adopts the modular design principle, which can be flexibly configured according to the space structure of the building and the actual use demand.

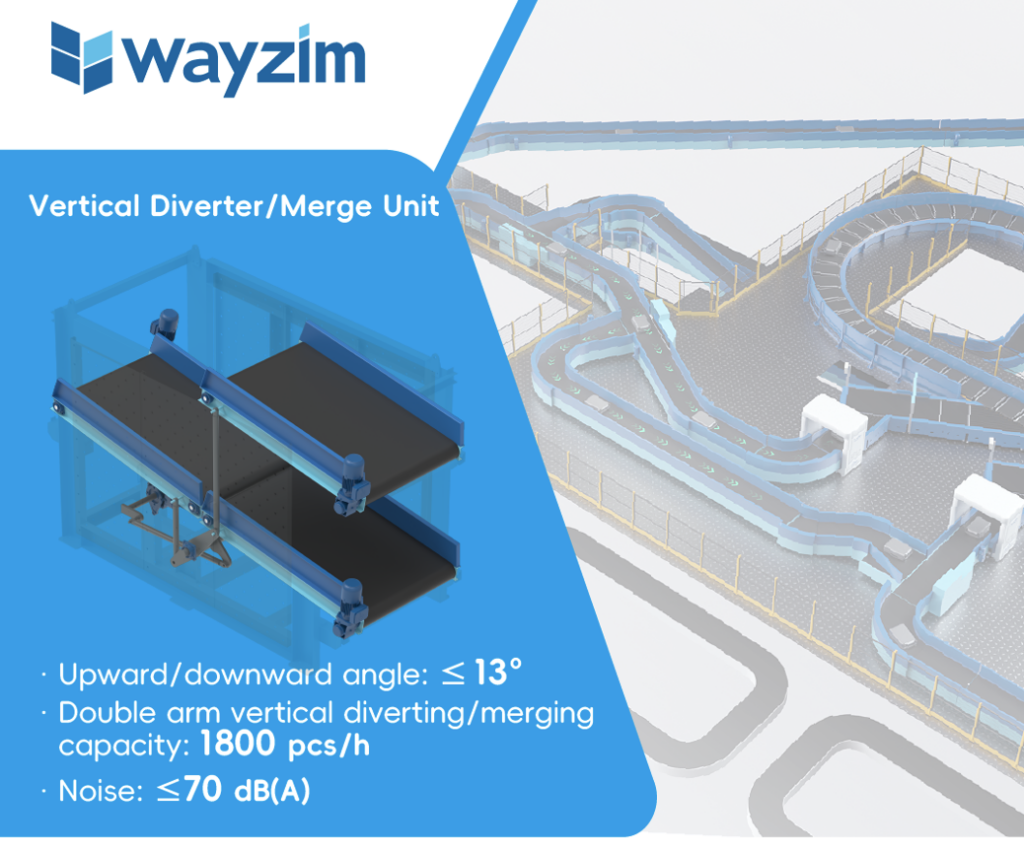

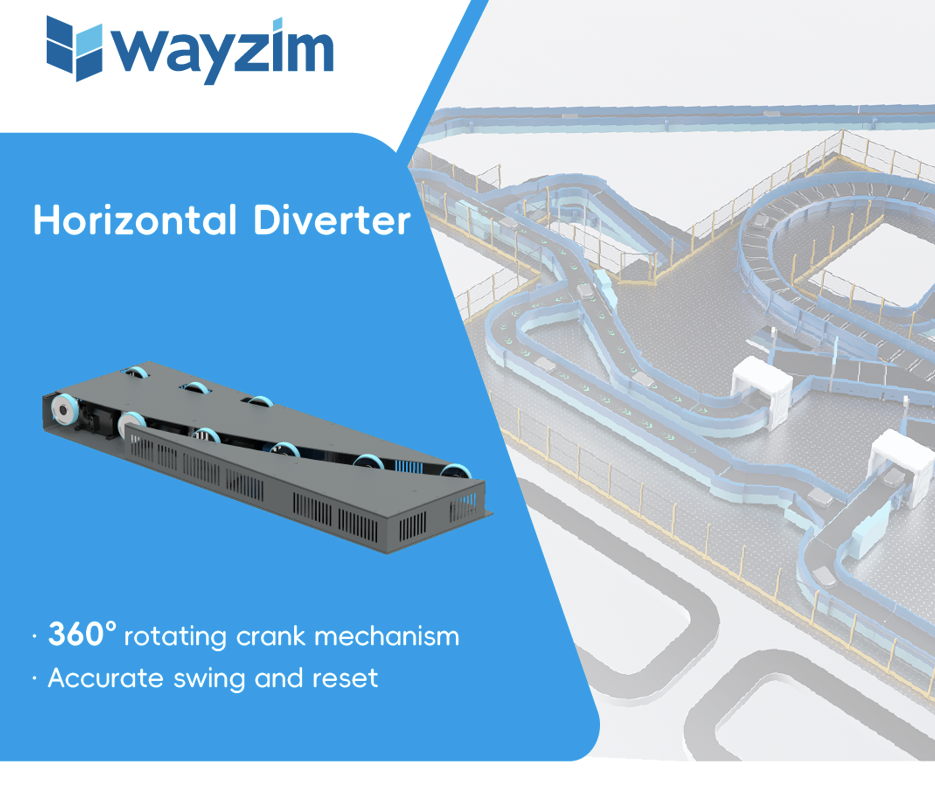

The diverting/merging system is composed of horizontal diverter, horizontal conveyor and inclined conveyor, realizing precise split/combined flow conveyor of baggage, which can be flexibly configured according to the space structure of the building and the actual use requirements.

- Smooth transport: Optimized paths during peak hours: The system arranges appropriate paths for baggage to ensure efficient and stable transport.

- Accurate tracking: Full-time tracking: Provides precise baggage tracking at all times to ensure safe baggage circulation.

- Energy-efficient transport: Intelligent control system: Automatically stops the equipment to save energy when detecting that there is no baggage on the conveyor belt.

Wayzim’s efficient and stable conveyor system can quickly and accurately transport baggage, solving the low efficiency, high energy consumption, and item loss problems of traditional conveyors. Horizontal conveyors are responsible for transporting luggage from one location to another, while inclined conveyors can easily handle the needs of transporting luggage at different heights. Curve conveyor overcomes the issues of congestion and damage that may occur when luggage turns corners. Diverter/merge unit flexibly diverts and merges luggage flows, enhancing overall transportation efficiency.

Linear conveyor is a belt-carrying conveying equipment, which adopts modular design, and flexibly configures the belt width, length, speed, and inclination angle according to the system requirements to realize linear horizontal or inclined conveying of luggage.

Queuing conveyor is a conveying equipment for separating or unitizing baggage, which can be flexibly deployed in the diversion, merging, security check and introduction line of the conveying line, so that the baggage can enter the next level of conveying line one by one.

Vertical diverter/merge unit consists of independent belt conveyor, oscillating crank link device, support frame, etc. Through the oscillating crank link device, the belt conveyor makes back and forth oscillating movement in the vertical direction to divert the baggage from one conveyor line to the upper and lower two levels of conveyor lines or merge the baggage from the upper and lower two levels of conveyor lines to one conveyor line to realize the diverter/combiner conveyor operation of the baggage.

The horizontal diverter consists of a rotatable swing arm conveyor, crank linkage mechanism and a protective cover, which realizes horizontal baggage diversion through the swing arm in the face of peak baggage handling, and easily copes with peak baggage diversion problems.

Our conveyor system ensures not only smooth transportation but also precise tracking of each piece of luggage, making luggage transport more efficient and reliable than ever before.

*Product information from our partner: Wayzim Technology.