Out of many Automation Products, AGVs are known to be one of the essentials in warehouse automation. Automated Guided Vehicles (AGVs) are material handling systems that follow defined paths or guides to transport materials within a facility. They are commonly used in warehouses, manufacturing plants, and distribution centres to automate repetitive material movement tasks. AGVs offer several advantages over traditional manual material handling methods, including improved safety, increased efficiency, and reduced labor costs.

Types of AGVs

There are several different types of AGVs, each with its own capabilities and applications:

1.Wire-guided AGVs:

Wire-guided AGVs follow a physical wire embedded in the floor to navigate. These AGVs are typically used for simple, repetitive tasks.

2.Laser-guided AGVs:

Laser-guided AGVs use lasers to reflect off of reflectors or markers in the environment to determine their position and navigate autonomously. These AGVs are more flexible than wire-guided AGVs and can handle more complex routes.

3.Vision-guided AGVs:

Vision-guided AGVs use cameras to identify and track features in the environment, such as barcodes or QR codes, to navigate. These AGVs are the most sophisticated type of AGV and can handle the most complex and dynamic environments.

4. Natural feature navigation AGVs:

Natural feature navigation AGVs use artificial intelligence (AI) to learn and map their environment, allowing them to navigate without the need for physical guides or markers. These AGVs are still in the early stages of development, but they have the potential to be the most versatile and adaptable type of AGV.

Schedule a call with SmartLogitecX

Benefits of Automated Guided Vehicles (AGVs)

Automated Guided Vehicles (AGVs) offer several benefits over traditional manual material handling methods, including:

Improved safety:

Automated Guided Vehicles eliminate the need for human operators to manually move materials, reducing the risk of accidents and injuries.

Increased efficiency:

AGVs can operate continuously and efficiently, moving materials faster and more accurately than human operators.

Reduced labor costs:

AGVs can automate repetitive material handling tasks, reducing the need for manual labor and associated labor costs.

Improved space utilisation:

Automated Guided Vehicles can operate in narrow aisles and high-bay environments, making more efficient use of available warehouse space.

Reduced product damage:

AGVs can handle materials gently and precisely, reducing the risk of product damage.

Applications of Automated Guided Vehicles

Automated Guided Vehicles are used in a wide variety of industries and applications, including:

Warehousing and distribution:

Automated Guided Vehicles are commonly used in warehouses and distribution centres to transport materials between storage areas, picking stations, and shipping docks.

Manufacturing:

AGVs are used in manufacturing plants to transport materials between work cells, assembly lines, and production lines.

Healthcare:

Automated Guided Vehicles are used in hospitals and healthcare facilities to transport supplies, medications, and patient samples.

Food and beverage:

AGVs are used in food and beverage processing plants to transport raw materials, ingredients, and finished products

Automotive:

Automated Guided Vehicles are used in automotive manufacturing plants to transport parts and components between assembly lines.

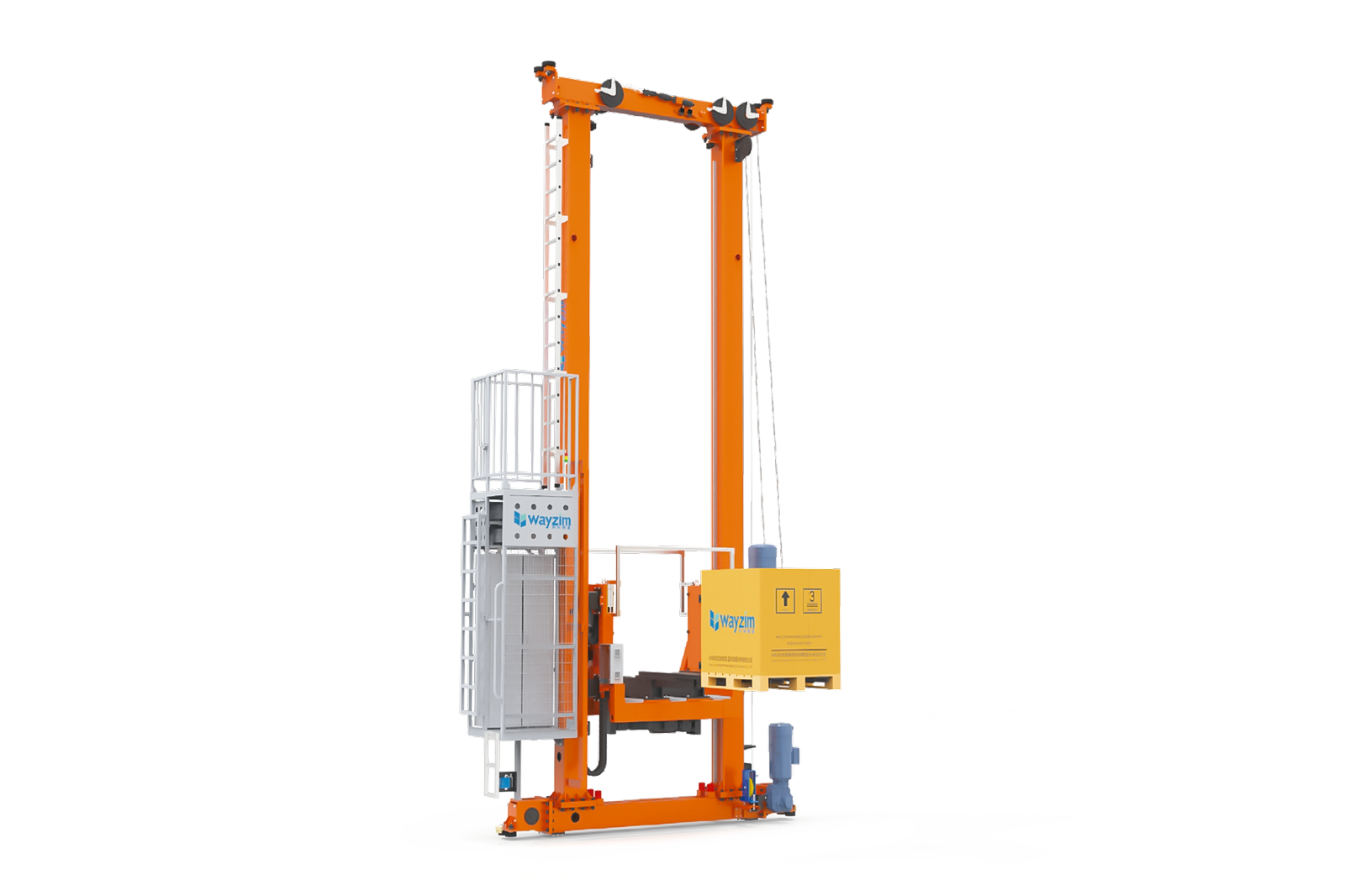

Comparison of Automated Guided Vehicles (AGVs) and Automated Storage and Retrieval Systems (ASRS)

AGVs and ASRS are both material handling systems that can automate the movement of materials. However, there are some key differences between the two systems.

| Automated Guided Vehicles (AGVs) | Automated Storage and Retrieval System (ASRS) |

| Mobile – Can be used to transport materials between different locations. | Stationary – Limited to retrieving and storing materials within a designated storage area. |

| Typically used to transport larger loads. | Typically used to transport smaller loads. |

| More flexible – Can be easily reprogrammed to follow different paths. | Less flexible |

The best system for a particular application will depend on the specific needs of the facility. In some cases, it may be necessary to use a combination of AGVs and ASRS to achieve the desired level of efficiency and productivity.

RELATED: Frequently Asked Questions on AGVs and AMRs

Join forces with SmartlogitecX, backed by the technological strength of WayZim Technologies, and lead the charge in Warehouse Automation in Australia and New Zealand. We are more than a service; we are your strategic partner in redefining logistics. Opt for SmartlogitecX to harness the full potential of advanced technology, crafted with an understanding of the local market. Connect with our sales team to begin your journey towards an automated, efficient future.