In the modern logistics industry, efficient and accurate sorting constitutes the bedrock upon which an entire logistics system operates smoothly. As the core system in a sorting process, the conventional 2D Bulk Flow Singulator System enhances the sorting efficiency of the overall process. But when there is an overwhelming surge in parcels and a deluge of deliveries, a conventional 2D Bulk Flow Singulator struggles to keep up. In response to this demand, Wayzim Technology Co., Ltd. (hereinafter referred to as Wayzim) has launched an innovative 10K 2D Bulk Flow Singulator System that enhances sorting efficiency and accuracy beyond the conventional 2D singulation technology. This contributes to the growth of the logistics industry.

This system has been successfully certified and put into operation by a top express delivery company in the industry. The system efficiently processes a vast volume of parcels while maintaining consistent sorting speeds and distances, significantly enhancing the overall sorting efficiency and accuracy.

【Technical Principle】

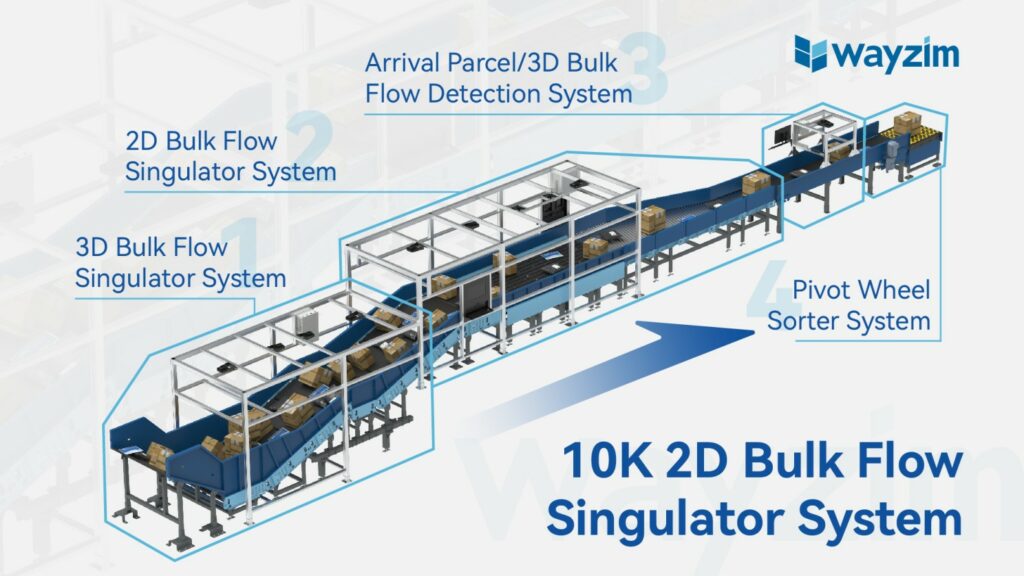

The 10K 2D Bulk Flow Singulator System is typically employed at the front end of automated sorting systems. It consists of a Spatial 3D Bulk Flow Singulator System, a Horizontal 2D Bulk Flow Singulator System, an Arrival Parcel/3D Bulk Flow Detection System, a Pivot Wheel Sorter System, and a Gapper (optional). The system is critical in logistics solutions and directly impacts the overall performance of the logistics industry.

This system enhances the automated processing capability of various types of parcels, from receiving and unloading, classification and removal, sorting, and loading, to distribution, through efficient 2D singulation, gap adjustment, and stacked parcel recognition and removal technologies.

【Product Advantages】

Hardware Upgrade

Wayzim has deeply understood customer needs and made significant improvements and upgrades to the hardware system.

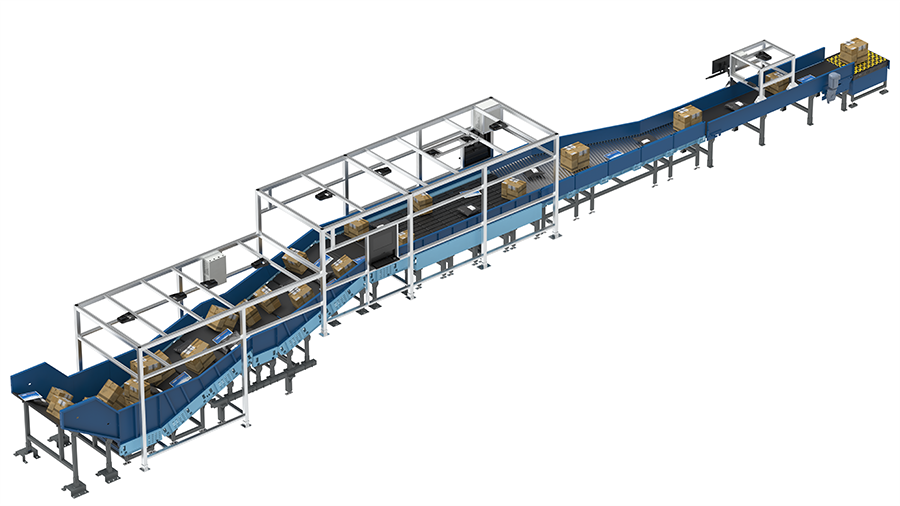

1. A wider and longer input end and more singulation modules are used.

This allows stacked parcels to be singulated on more falling sections. The system operates more smoothly with smaller gap errors and provides better handling of piled parcels.

2. The Alignment Conveyor uses single-row rollers.

This prevents parcels from slipping during conveying, which effectively improves parcel output stability and reduces gap fluctuations.

3. A visual recognition system with a broad field of view is used at the end, coupled with the Pivot Wheel Sorter.

This helps remove non-conforming items such as items whose width exceeds the limit, stacked items, and items that are too close to each other, and further enhances sorting accuracy.

4. The entire system is controlled by servo systems.

Distinguished from the conventional DC motor drive method, this further enhances system stability and control accuracy.

5. The equipment boasts exceptional low-temperature adaptability, enabling it to operate stably in extremely cold environments down to –30°C.

【Visual Algorithm】

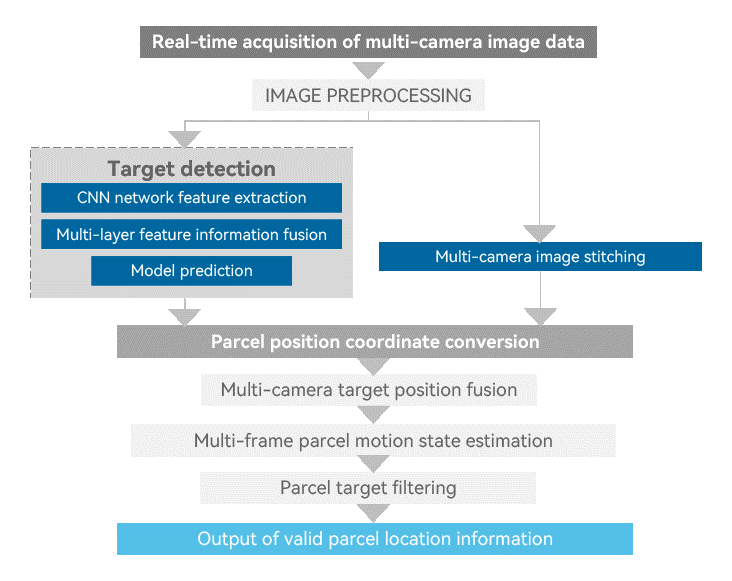

The 10K 2D Bulk Flow Singulator System uses Wayzim’s proprietary detection technology for all types of parcels, including the multi-camera image stitching and fusion technology, deep learning-based high-precision parcel positioning technology, deep learning-based parcel segmentation technology, as well as real-time parcel tracking technology. The system can easily handle black parcels, consolidation bags, and envelopes, and accurately and efficiently determine the position and stacking status of parcels on the conveyor belt, enabling the efficient sorting of express parcels.

【Software Support】

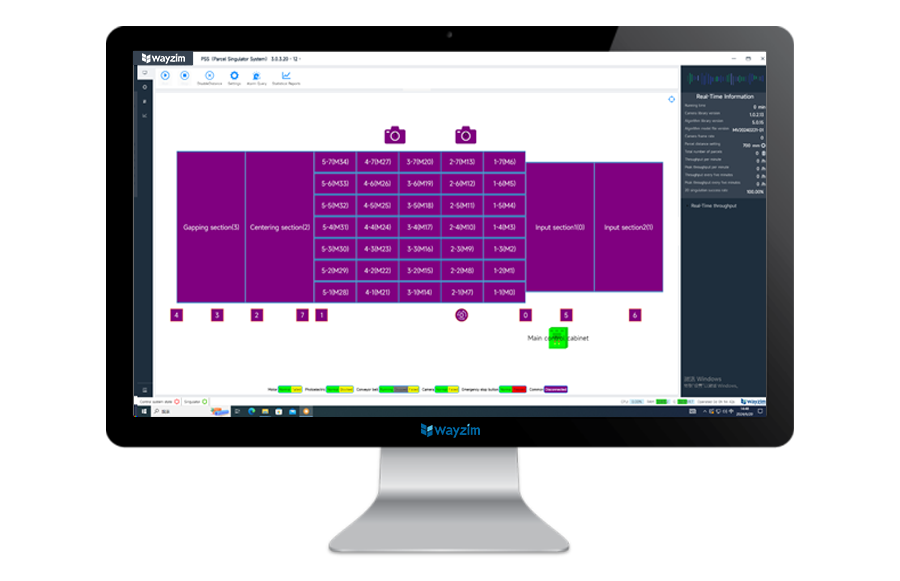

The 10K 2D Bulk Flow Singulator System uses PSS software to visually monitor and manage equipment for real-time display of equipment running status. The software provides a comprehensive solution for managing the operation of the system and greatly enhances equipment management efficiency and accuracy.

Key system functions

1. Status and data display

Different colors are used to indicate equipment running statuses, including but not limited to running, delayed startup, hibernation, fault, maintenance, emergency stop, and jam warning statuses.

The software provides critical performance indicators such as system throughput, singulation success rate, and average parcel length to display sorting efficiency.

2. View modes

The software provides two view modes—camera view and global view. These modes allow users to directly view the working statuses of cameras and singulators and observe the running status of each servo motor in the singulation area, enabling smooth handling of unexpected situations.

【Summary】

As a remarkable innovation in the logistics technology field, the 10K 2D Bulk Flow Singulator System sets a new benchmark for the logistics sorting field. The system, with a refined operation process and robust automated sorting capabilities, not only reduces labor costs but also significantly enhances the processing capacity and overall operational efficiency of enterprise logistics centers. Besides the significant advantages in the logistics sorting industry, in conjunction with intelligent handling devices such as four-way shuttles, it can further expand its application scope, providing comprehensive logistics solutions integrating intelligent sorting and automated storage for industries including intelligent warehousing and e-commerce.